DRYING

Belt dryer

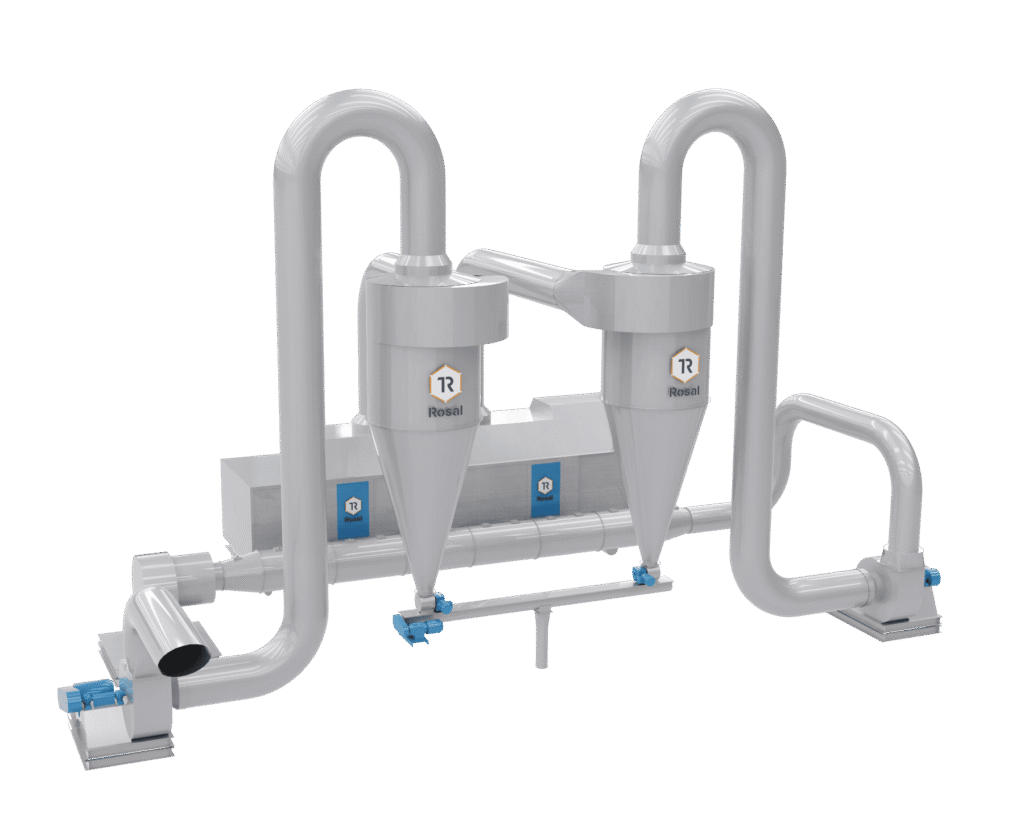

Industrial belt drying utilizes long holding times and low air temperatures, making it ideal for extruded animal feed and forestry products. These dryers operate with an indirect heat supply system using heat exchange coils.

Features

Process

Operation and air distribution

The belt dryer is designed to provide a uniform feed, which ensures a balanced drying of the product. It is placed on variable speed trays, maintaining a constant layer height. On the sides of the drying chamber, hot air inlets are located to initiate a flow that runs throughout the interior of the chamber, passing through the holes in the trays to ensure efficient drying.

Request more information

Leave us your data and questions and a belt dryer technician will advise you without obligation. Let's talk!

Related machinery

Drum dryer

The rotary drum dryer achieves minimum moisture content in the final product.

Extruder

The Rosal extruder is designed to manufacture high quality extruded food for dogs, cats, fish and cereals.

Pellet mill

Mabrik industrial pellet mills are built with high quality materials and great robustness.

Hammer mill

Our hammer mills guarantee efficient and uniform grain grinding.