GRINDING

Roller mill

Features

Design

Independent drive and high-strength grinding chamber

The roller mill has an independent drive for each floor, with motor and transmission by pulleys and toothed belts.

The grinding chamber is made of high-strength steel plate for durability and includes a high-powered magnet for separation of metal particles.

Models

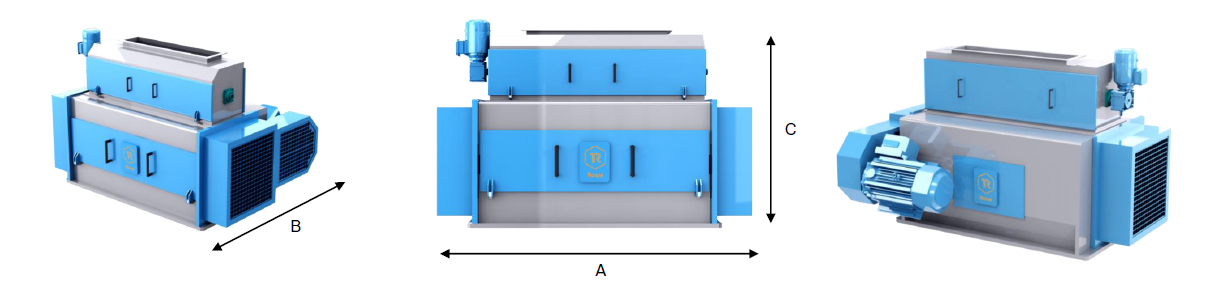

| Model | Motor power (HP) | Roller diameter | Roller length | A | B | C | Capacity (Tm/h) | Weight (Kg) |

|---|---|---|---|---|---|---|---|---|

| MRR 2008 D | 2 x 15 (11 kW) | 200 | 800 | 1460 | 1260 | 1370 | 14 - 18 | 1900 |

| MRR 2512 D | 2 x 25 (18.5 kW) | 250 | 1250 | 1990 | 1540 | 1580 | 25 - 30 | 3800 |

| MRR 3015 D | 2 x 40 (30 kW) | 300 | 1500 | 2340 | 1690 | 1790 | 40 - 50 | 5800 |

Frequently Asked Questions

The roller mill is an equipment used in animal feed mills to grind grains such as corn, wheat or soybeans. By means of the opposite rotation of two or more rollers, the material is shredded and reduced in size, which facilitates its mixing and subsequent pelletizing.

In a feed mill, the roller mill is used in the milling stage after screening and before mixing. This process ensures optimum cleanliness and uniformity of the grain for subsequent mixing.

Our roller mills are specially designed to meet the needs of the agro-industrial sector:

Compound feed mills

Cereal processing plants

Flour mills

Pet food factories

Biomass plants

Extrusion plants

Oilseed handling

Handling of cereals, flours and their by-products in general

Product flow is controlled by a manual feed valve. It should be opened as little as necessary to avoid overloading or clogging. Too much product can hinder automatic regulation and affect mill performance.

The roller mill requires regular maintenance, which includes:

Grease after a certain number of working hours.

Periodic adjustment of belts and springs to ensure proper operation.

Frequent cleaning of the magnet to avoid accumulation of metal particles.

Revision of the limit switches to maintain safety during operation.

The roller gap can be adjusted manually by handwheels or automatically with an electric motor and encoder. Correct adjustment ensures precise and uniform grinding, which is essential for feed quality. In both cases, it is necessary to check the distance with gauges and make sure to respect the mechanical safety stops.

If they are loose, unground or improperly sized grain may pass through.

If they are too tight, the rollers may be damaged by overloading or foreign bodies.

Request more information

Leave us your data and questions and a roller mill technician will advise you without obligation. Let's talk!

Related machinery

Hammer mill

Our hammer mills guarantee efficient and uniform grain grinding.

Flaking mill

The flaking mill produces cereal flakes, ideal for livestock due to their optimal digestibility.