PELLETING

Pellet conditioner

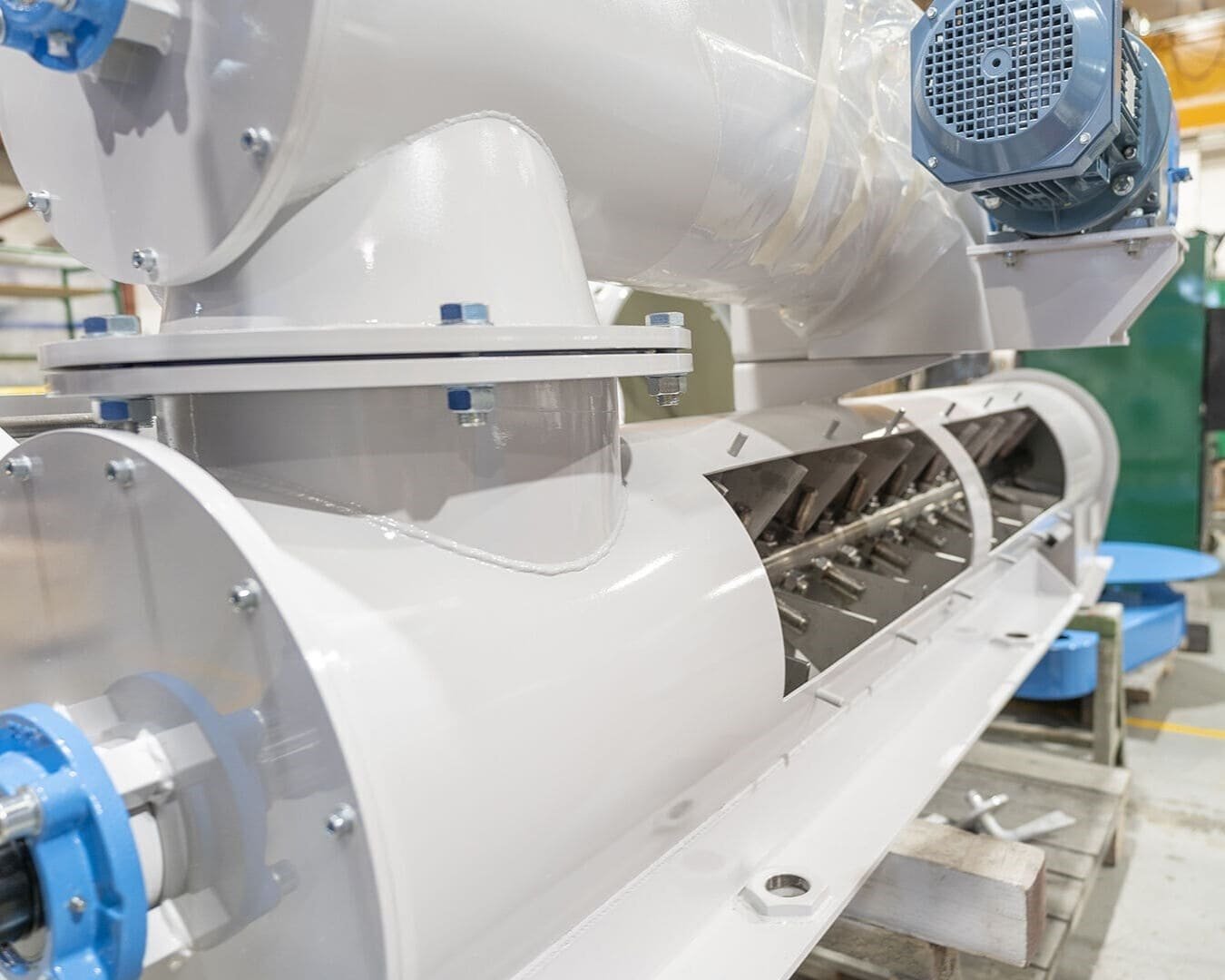

The pellet conditioners generate the necessary heat treatment to prepare the product prior to pelletizing, which is key to obtaining quality pellets and increasing yield.

Mabrik pelelt conditioners improve homogenization by mixing steam and liquids, intensifying the heat treatment of the flours. This improves the quality of the final product, favors the elimination of bacteria and increases digestibility in animals.

Features

Efficiency

Mixing system

The pellet conditioner is designed to receive steam and liquids, and has inspection doors for easy maintenance and cleaning. Its capacity can be adjusted according to the needs or type of product to be processed. Both the housing and the shaft are made of stainless steel to ensure durability and strength.

Versatility

Adjustable blades

The blades of the pellet conditioner are made of stainless steel and are adjustable to adapt to different types of products, optimizing the mixing process according to specific needs.

Image gallery

Related machinery

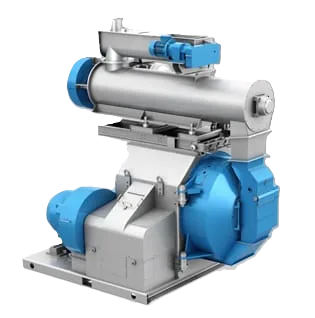

Pellet mill

Mabrik industrial pellet mills are built with high quality materials and great robustness.

Counterflow cooler

Mabrik counterflow coolers are designed to cool the pellets coming out of the pelletizing process.

Hygieniser

The hygieniser is designed to reduce and eliminate pathogens in compound feed.