PELLETING

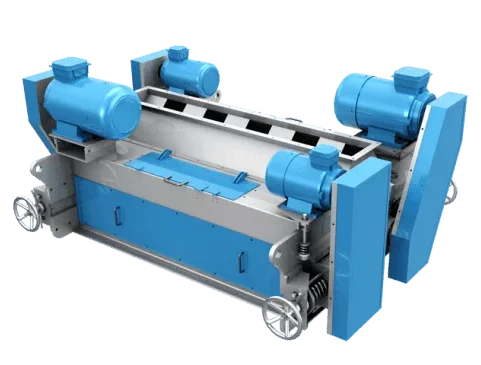

Pellet crumbler

Features

Design

Rollers

Each roller is individually driven by an electric motor and the transmission is by V-belts.

The roller adjustment system (forward-reverse) is carried out by means of a handwheel with damping springs and micrometric distance indicators.

Design

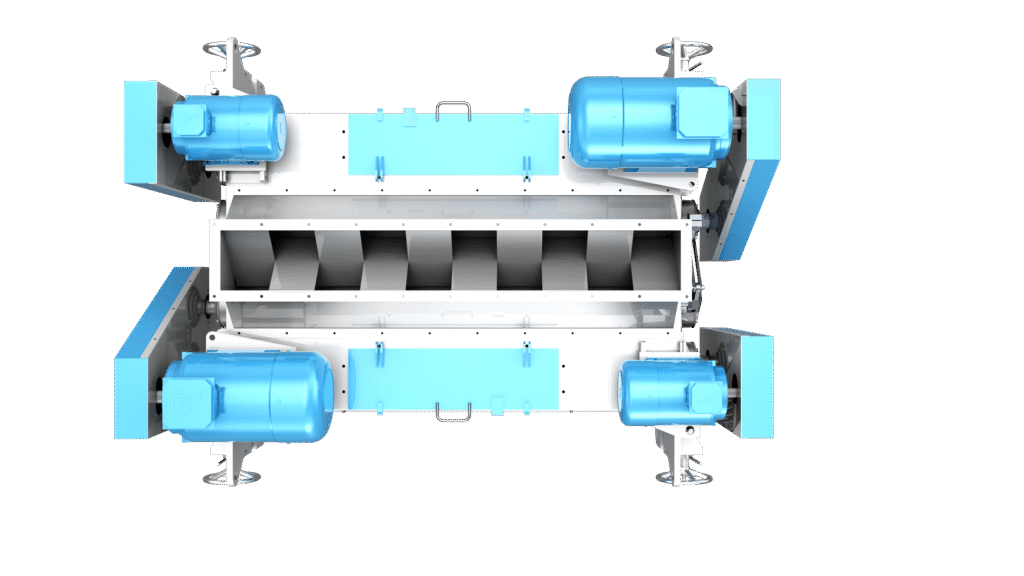

Bypass damper

Its configuration with independent motors and integrated bypass allows easy switching between work mode and straight through, optimizing flow and process efficiency.

Models

Each shredder model can be manual or automatic: the manual version adjusts the opening with handwheels and indicators, and the automatic version is motorized and electronically controlled, suitable for automated systems.

| Model | Roller diameter (mm) | Number of rollers | Motor power (kW) | Estimated production (Tn/h) |

|---|---|---|---|---|

| DR 220 | 200 | 2 | 7,5 / 15 | 15 |

| DR 225 | 250 | 2 | 7,5 / 22 | 22 |

| DR 420 | 200 | 4 | 2x7,5 / 2x15 | 30 |

| DR 425 | 250 | 4 | 2x7,5 / 2x22 | 45 |

Frequently Asked Questions

The pellet falls onto a system of counter-rotating rollers that shred the pellet. The distance between rollers, which can be adjusted, determines the final size of the shredded product.

The manual model allows roller opening to be adjusted by handwheels and mechanical indicators. The automatic model incorporates motors and electronic control for precise adjustment, more suitable for automated lines.

Yes, it has a bypass system, which allows the product to be diverted without passing through the rollers when shredding is not required, facilitating flexible use without stopping production.

Grooved steel rollers with special horizontal and vertical reliefs, designed for efficient pellet breaking without generating excessive dust.

Through a feeder with frequency converter, which adjusts the speed according to the load, avoiding overloads and maintaining a constant flow of product.

Regular cleaning, roller wear control, belt tensioning and verification of safety elements. Maintenance is simple if the established protocols are followed.

Request more information

Leave us your data and questions and a pelletizing shredder technician will advise you without obligation. Let's talk!

Related machinery

Pellet mill

Mabrik industrial pellet mills are built with high quality materials and great robustness.

Counterflow cooler

Mabrik counterflow coolers are designed to cool the pellets coming out of the pelletizing process.

Hygieniser

The sanitizer is designed to reduce and eliminate pathogens in the compound feed.

Coater

Regreasers are equipment designed to optimize the final quality of the feed, allowing the precise addition of fat, oil or other liquids to the pellet.