PELLETING

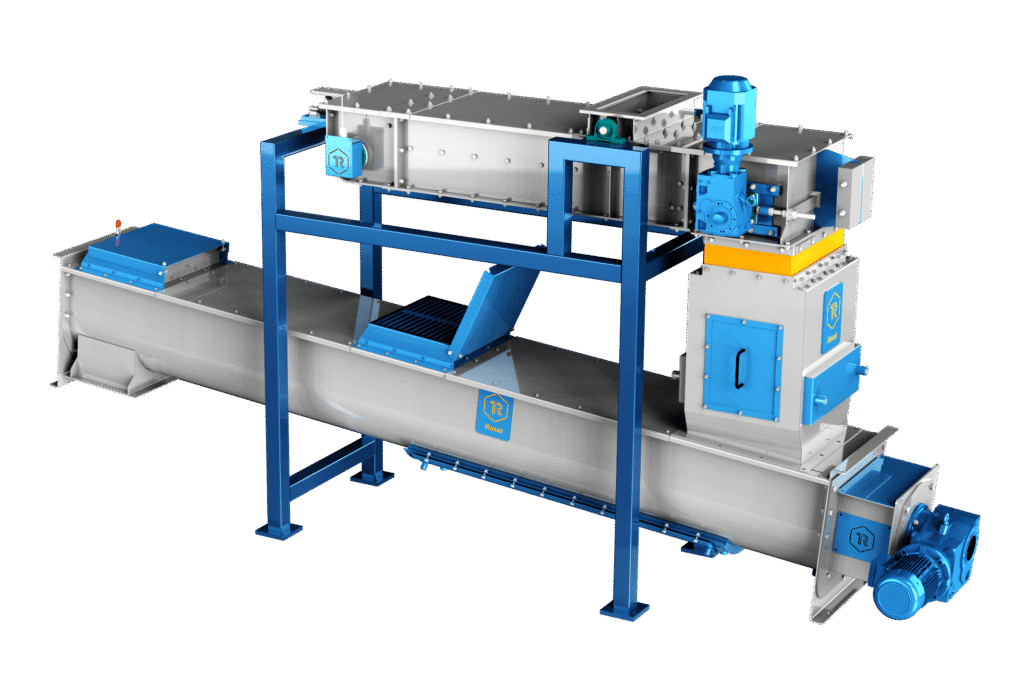

Coater

Coaters are equipment designed to optimize the final quality of the feed, allowing the precise addition of fat, oil or other liquids to the pellet prior to dispatch. This process improves the adherence of liquids, ensuring a uniform coating that increases the nutritional value and properties of the feed.

With coaters, an ideal pellet finish is achieved, guaranteeing its rigidity, reducing the generation of fines and allowing the efficient incorporation of supplements such as enzymes, vitamins or specific additives. The result is a high quality balanced feed, with greater durability, better digestibility and excellent palatability, key factors to optimize animal performance and meet market demands.

Features

Design

Coating system for pellets

Coaters with continuous flow scale, chamber for oil application, continuous or batch conditioner for enzymes, hot water chamber, stainless steel body and practicable design for complete cleaning.

Request more information

Leave us your data and questions and a pelletizing regreaser technician will advise you without obligation. Let's talk!

Related machinery

Pellet mill

Mabrik industrial pellet mills are built with high quality materials and great robustness.

Pellet conditioner

Conditioners generate the heat treatment necessary to prepare the product prior to pelletizing.

Counterflow cooler

Mabrik counterflow coolers are designed to cool the pellets coming out of the pelletizing process.

Hygieniser

The sanitizer is designed to reduce and eliminate pathogens in the compound feed.