PELLETING

Mabrik Pellet Mills

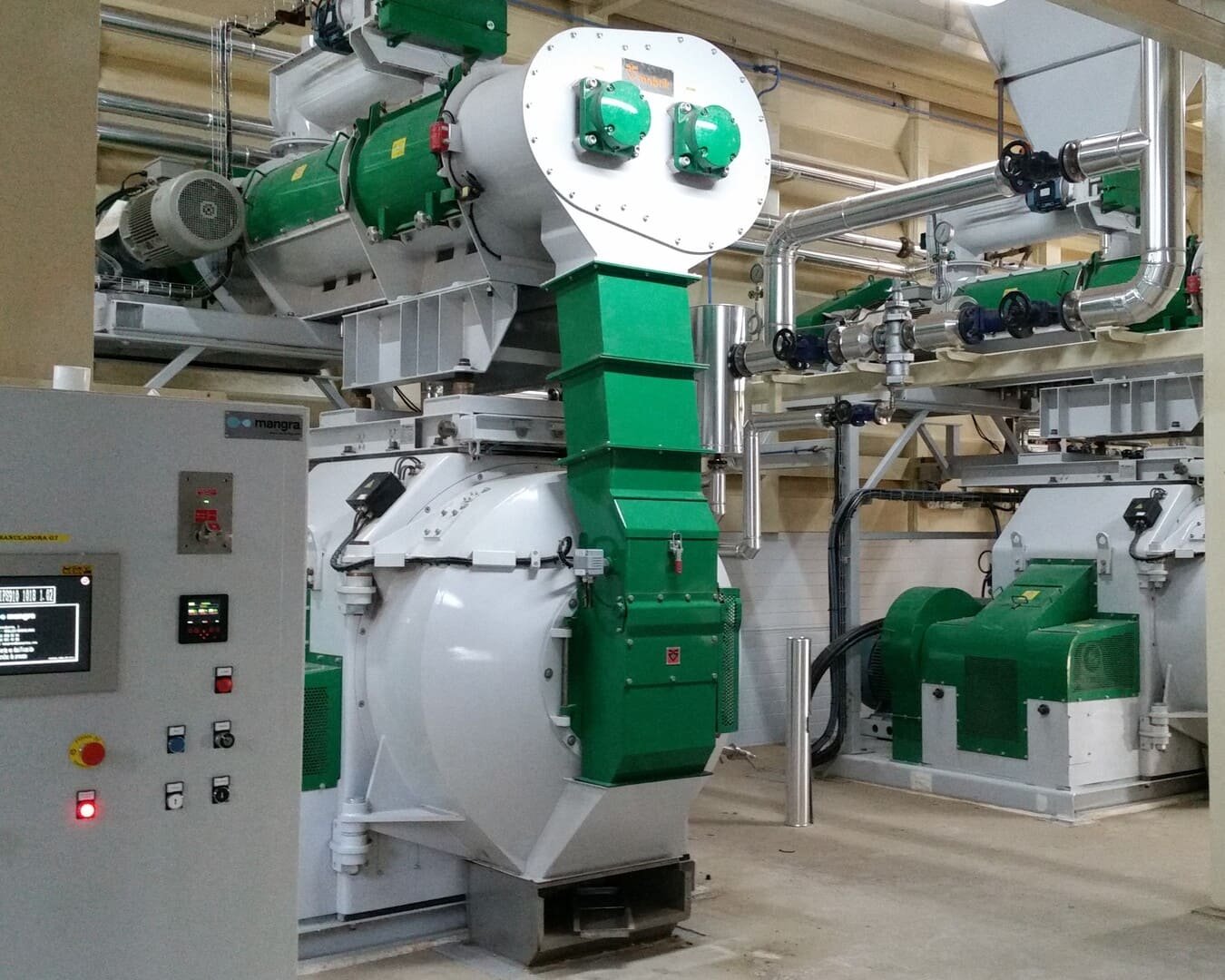

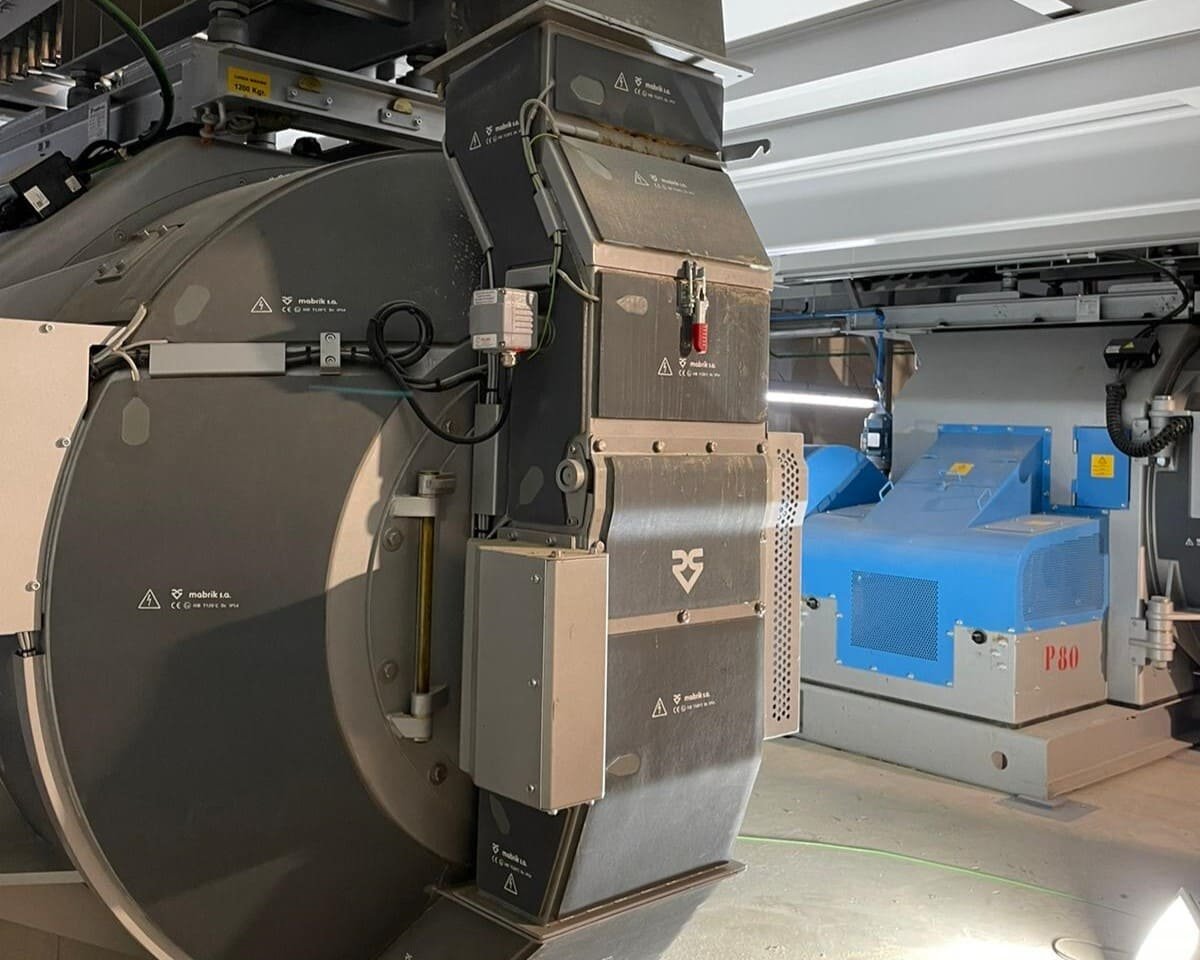

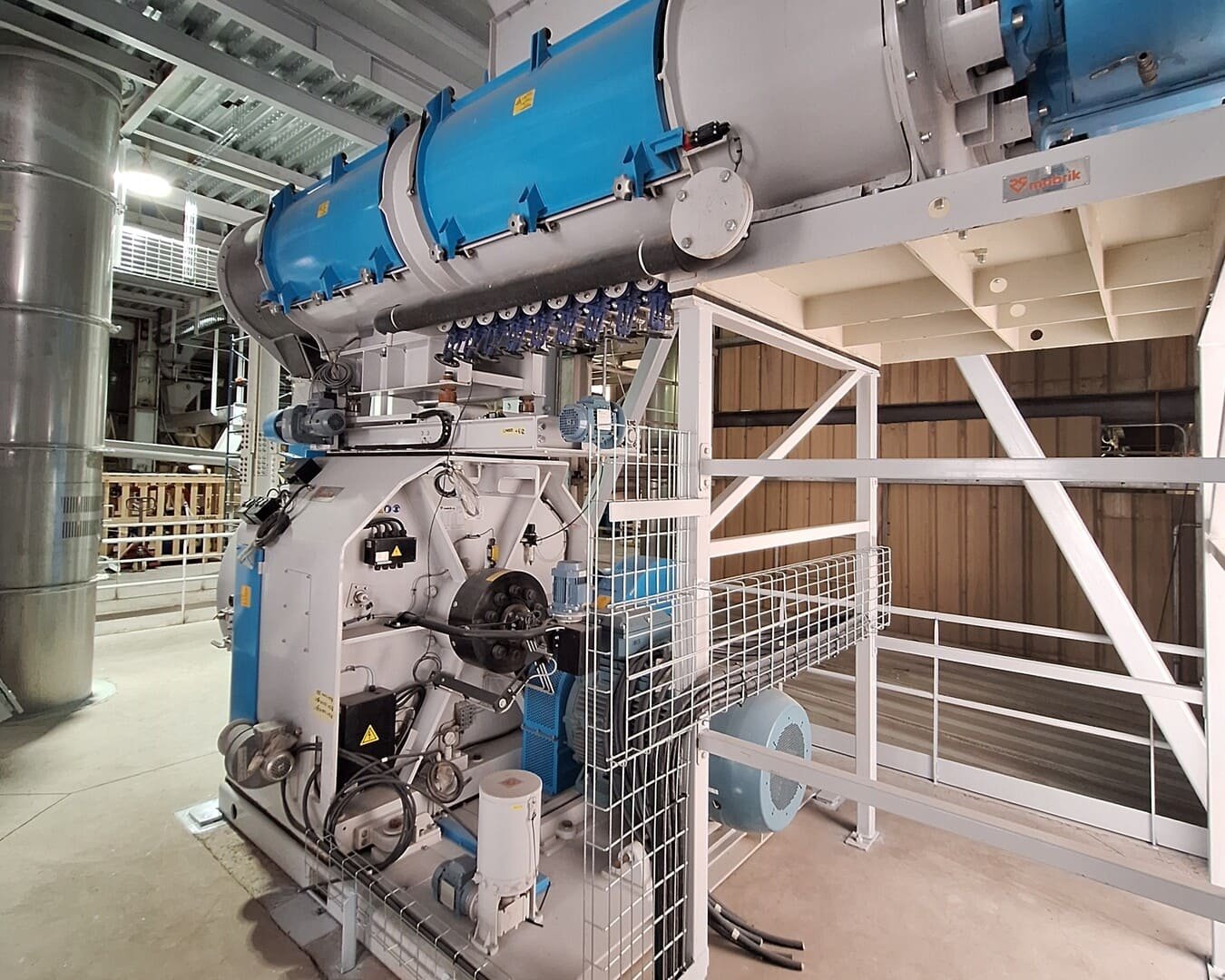

Mabrik industrial pellet mills are built with high quality materials and great robustness.

Its design incorporates high dynamic and static load bearings that allow it to work with maximum reliability and in the toughest conditions, such as the pelleting of alfalfa, by-products, residues, wood, etc.

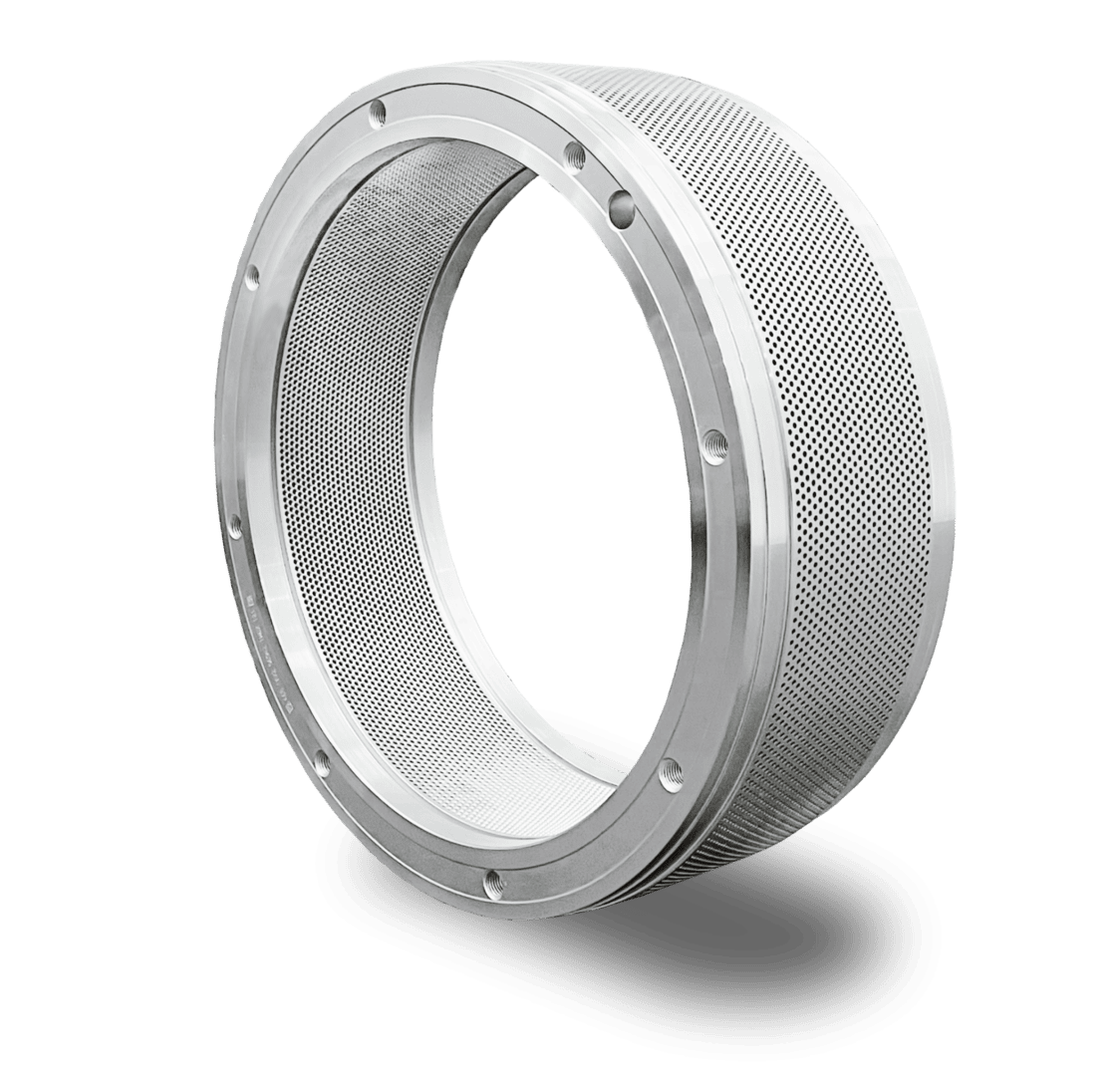

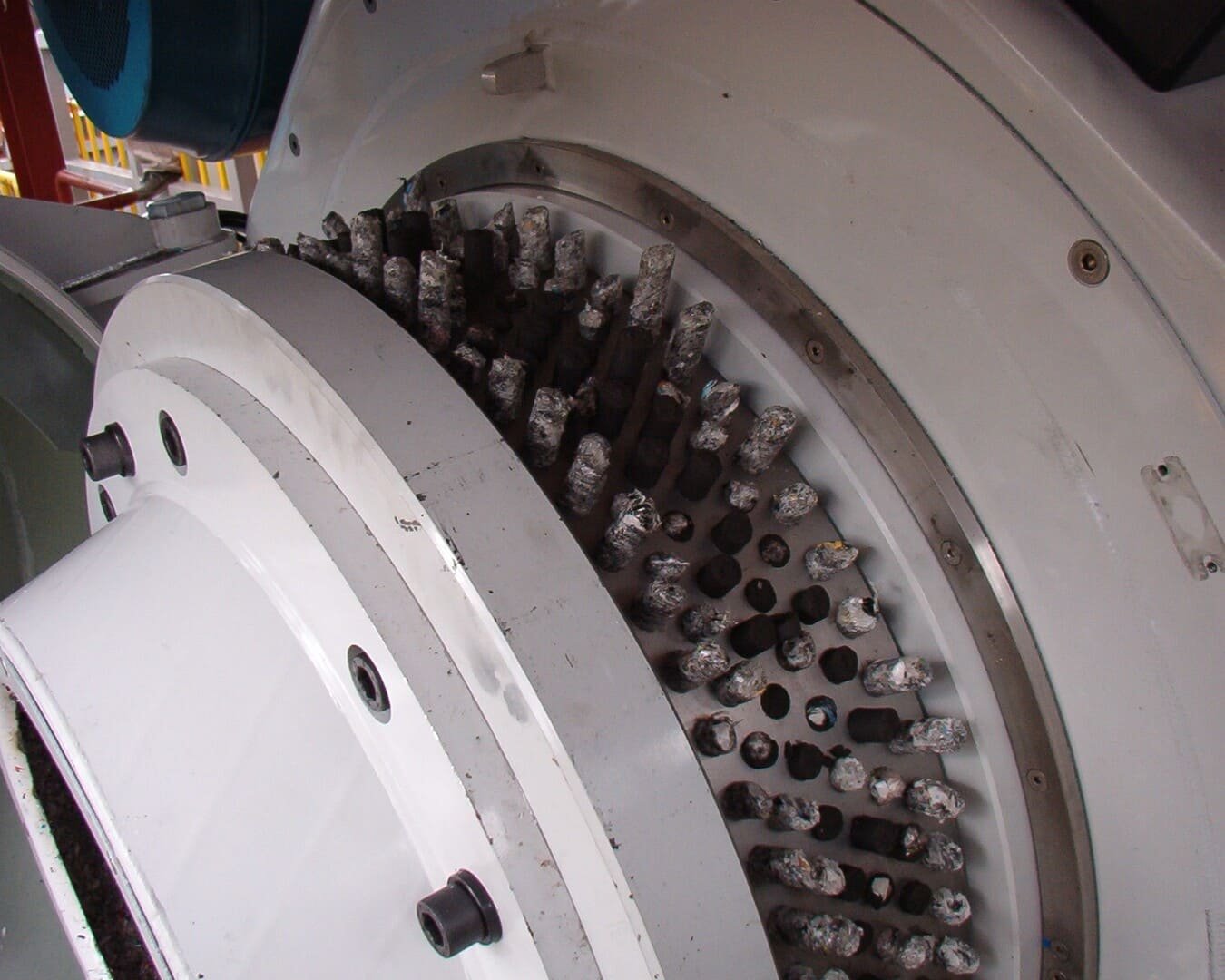

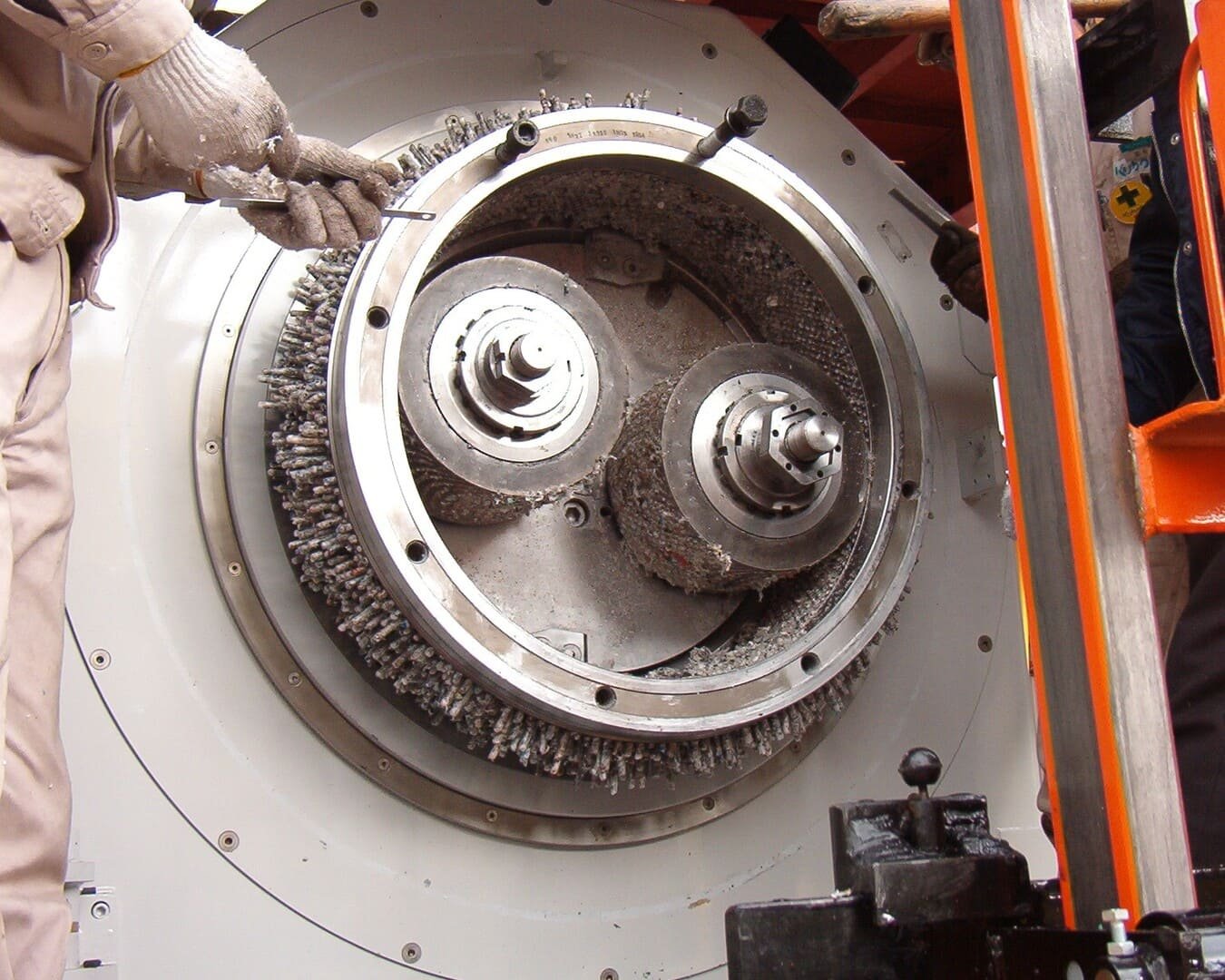

Mabrik also specializes in the production of dies, built with the best quality steels and using the most modern technology for their execution, heat treatment and finishing. Dies are manufactured for all types of pellet mills, using case hardening steel and stainless steel, bores of different diameters -from 1.8 to 25 mm- and special shapes (squares, cookies, among many others).

Features

Models

Pellet mill models

Thinking of all possible pelleting fields, Mabrik has created different lines of pellet mills:

- PVB Models:Pellet mills with motor on the baseplate are models with high rigidity and particularly smooth operation due to their rubber insulation. These pellet mills are the most advanced models and are especially recommended for pelleting difficult products.

- PVR models: Pellet mills with a compact design with the motor located at the top, ideal for installation in confined spaces.

Design

Rollers and transmission

- Rollers:Depending on the product to be pelletized, the pellet mill can be configured with 2 or 3 manually adjustable rollers or with an automatic roller adjustment system "RA".

- Transmission:To adapt to the most suitable tangential speed for the product to be pelletized, we have different combinations of V-belt drives. We use the latest generation of V-belts achieving transmission efficiencies up to 98% and minimum maintenance.

Image gallery

Related machinery

Pellet conditioner

Conditioners generate the heat treatment necessary to prepare the product prior to pelletizing.

Counterflow cooler

Mabrik counterflow coolers are designed to cool the pellets coming out of the pelletizing process.

Hygieniser

The hygieniser is designed to reduce and eliminate pathogens in compound feed.