STORAGE

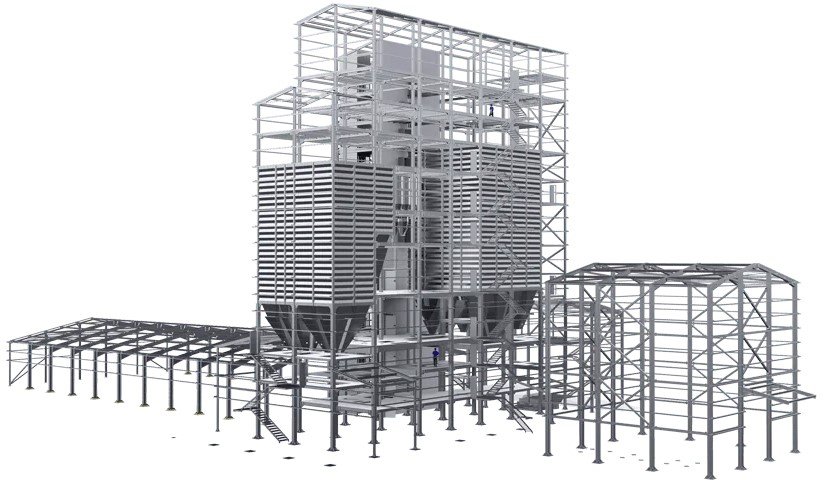

Steel structures

Our steel structures are specially designed to support the weight of the entire storage system of a feed mill.

We develop fully bolted structures, something that allows us to always guarantee the customer a final product with great finishes and of the highest quality.

We have a multidisciplinary team formed, among other professionals, by engineers and designers specialized in designing and calculating any type of metallic structure.

Features

Quality

Certified steel structures for feed mills

Our bolted structures are manufactured with standardized metal profiles and formed profiles, certified with CE marking by EXCO3 according to EN 1090-1:2009+A1:2011.

We comply with all safety and quality regulations, adapting to the standards of any country.

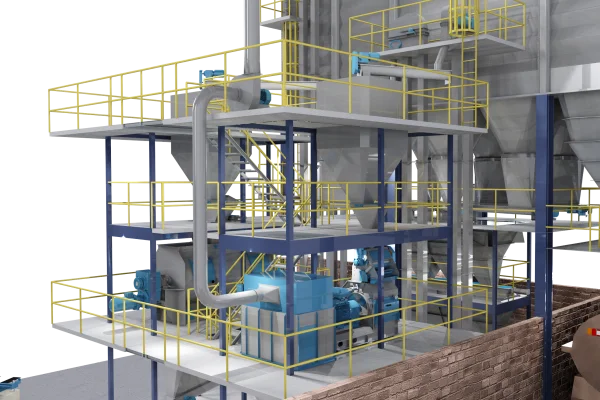

Modular systems

Containerized feed mills

More and more customers are choosing our containerized feed mills, a modular solution that reduces installation times and transportation costs. We carry out assembly and testing at our facilities, guaranteeing efficiency and safety. In addition, these plants have low energy consumption and a built-in electrical system.

Frequently Asked Questions

Yes, the horizontal earthquake acceleration is included in the design. This allows the structure to meet stability requirements for moderate seismic motions, according to the specified seismic zone.

Standardized profiles (IPE, UPN, HEA, etc.), assembled with screws. The use of standard profiles facilitates manufacturing, assembly, maintenance and future extensions.

With standardized metal profiles and a 1 mm thick slab. Reinforced concrete is poured on the slab, generating a resistant slab suitable for industrial loads.

140 mm high perimeter trims and handrails in risk areas. This complies with safety regulations for working at heights and prevents the fall of materials or people.

With 3 and 4 mm steel sheet folded in zig-zag, forming a monoblock by means of bolted shafts. This system provides high rigidity and facilitates the transport and assembly of modules.

Hoppers made of 4 mm sheet metal and reinforcing ribs with flat bars. The walls are inclined and with chamfered edges to ensure continuous discharge of the product without jamming.

The counter hopper complements the main hopper and facilitates product discharge. It has the same dimensions, reinforcements and technical characteristics, and includes an inspection register.

All parts are primed with anti-rust primer and industrial finish paint. This protects against moisture, dust and wear in continuous process environments.

Yes, the modular, bolt-on system allows for expansions without dismantling the existing structure. It is possible to add additional platforms, modules or hoppers adapted to new process steps.

Request more information

Leave us your data and questions and a technician in metallic structures will advise you without obligation. Let's talk!

Related machinery

Grain silos

Our silos are designed to offer efficient and safe storage solutions for bulk products.