SCREENING

Grain cleaner

Features

Design

Efficiency and protection in the separation process

Models

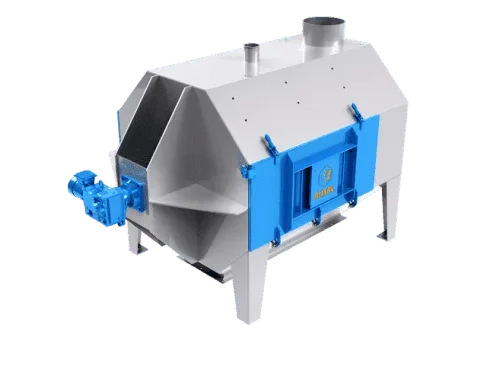

High-capacity grain cleaner

Rosal has a high capacity grain cleaner for industrial processes where large volumes of cereal need to be cleaned quickly and efficiently.

Processing capacity up to 150 tn/h.

5 sorting outputs: clean grains, small grains, residues, and dust separated in two stages.

Rotary screen system with a total area of 32 m² for efficient separation.

Double aspiration (inlet and outlet) that removes dust and chaff through vertical air flow.

Accessible and easily adjustable controls to optimize airflow.

Solid construction, designed for continuous operation with low maintenance.

Models

| Model | Screening area (m2) screening area (m2) | Capacity (m3/hour) |

|---|---|---|

| PR-70 | 1.6 | 20 - 75 |

| PR-100 | 3.6 | 36 - 135 |

| PR-140 | 6 | 66 - 225 |

| PR-160 | 10.7 | 102 - 300 |

| PR-200 | 17 | 143 - 338 |

| PR-200-E | 22.6 | 189 - 450 |

Frequently Asked Questions

A grain cleaner works by means of a screening and suction system that separates the grain from the impurities. The product enters the machine and passes through one or more perforated screens, where large impurities or small grains are retained depending on the size of the sieve. Simultaneously, an air suction system extracts light particles such as dust, straw or husks. The clean grain is collected through a specific outlet, while the residues are evacuated through separate channels. The whole process is continuous and automatic.

The grain cleaner is normally installed in the raw material receiving line, just after the unloading system (hoppers, weighbridge or truck pit). Its function is to clean the grain before storing it in silos or sending it to milling, preventing impurities from damaging the equipment or contaminating the final product.

The cleaners are mainly designed for cereals such as wheat, corn, barley, oats, rye, but can also be used for oilseeds, pulses or non-food granular products, provided they have a density and grain size compatible with the installed screens.

A grain cleaner can eliminate:

Large impurities: stones, branches, clods of earth, straw.

Dust and light particles by aspiration.

Broken or small grains by screening.

Non-usable waste according to the design of the outlets.

It depends on the type of cereal and the desired degree of cleanliness. In general:

Screens of 15-20 mm for wheat, oats, barley.

Screens of 25-30 mm for corn, sunflower or larger products.

The objective is to allow the passage of useful grain and to retain both large impurities and unwanted small grains.

Regular cleaning of screens, chambers and outlets.

Periodic greasing of bearings and seals.

Engine overhaul, direction of rotation, vibrations.

Inspection of closures, covers and safety protections.

Replacement of screens in case of wear or perforations.

Performance decreases when processing wet grain, as it tends to clog the screens, cause residue buildup, and reduce the efficiency of the aspiration system. It is recommended that the product be dry or pre-dried before entering the pre-cleaner.

Request more information

Leave us your data and questions and a precleaning technician will advise you without obligation. Let's talk!

Related machinery

Flour sifter

The sifter filters and separates foreign agents such as iron, stones or cardboard from the flours.

Rotary screen

Rotary screens are used to separate fines from pellets in different sizes and capacities.