Selecting the right grinding equipment is a critical decision that directly affects operational efficiency, production costs, and final product quality.

Both milling technologies have evolved significantly since their origins in the 19th century, when roller mills revolutionized the flour industry and hammer mills transformed feed processing. Today, this equipment is used across industries ranging from food to recycling.

This technical study examines in depth the physical principles, energy efficiency, particle size capabilities, operating costs and industrial applications of both systems, providing engineers and plant managers with the quantitative information needed to optimize their size reduction processes.

Comparison summary

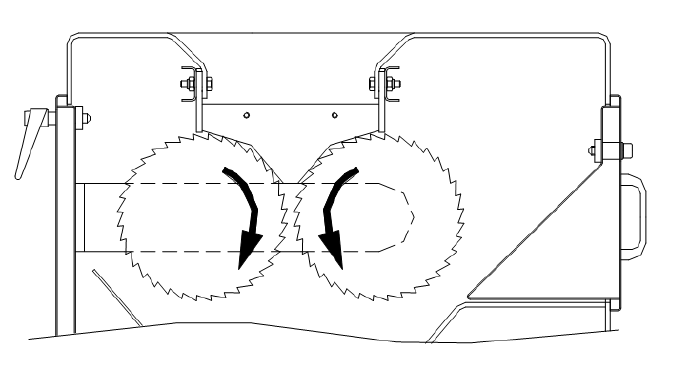

Hammer mills operate on the principle of impact, using rotating hammers mounted on a rotor that reaches speeds of 1500-3600 rpm. This mechanism generates peripheral velocities of between 70 and 120 m/s,producing impact forces between 5,000 and 15,000 N, fragmenting the material against the screens and internal walls of the grinding chamber.

On the other hand, the roller mills operate on the principle of compression and shear, operating at speeds significantly lower than 100-300 rpm. These systems typically apply specific pressures of 50-200 N/mm² between parallel cylinders with adjustable spacing of 0.1-3mm, achieving size reduction through controlled plastic deformation.

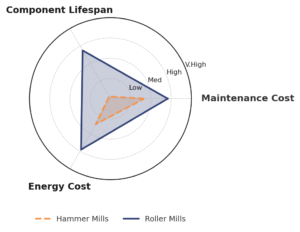

- Energy efficiency is one of the most significant differentiators. Roller mills demonstrate 15 to 25% lower energy consumption, typically operating between 8-12 kWh/ton, while hammer mills require 10-16 kWh/ton, with peaks up to 25 kWh/ton for high-hardness materials.

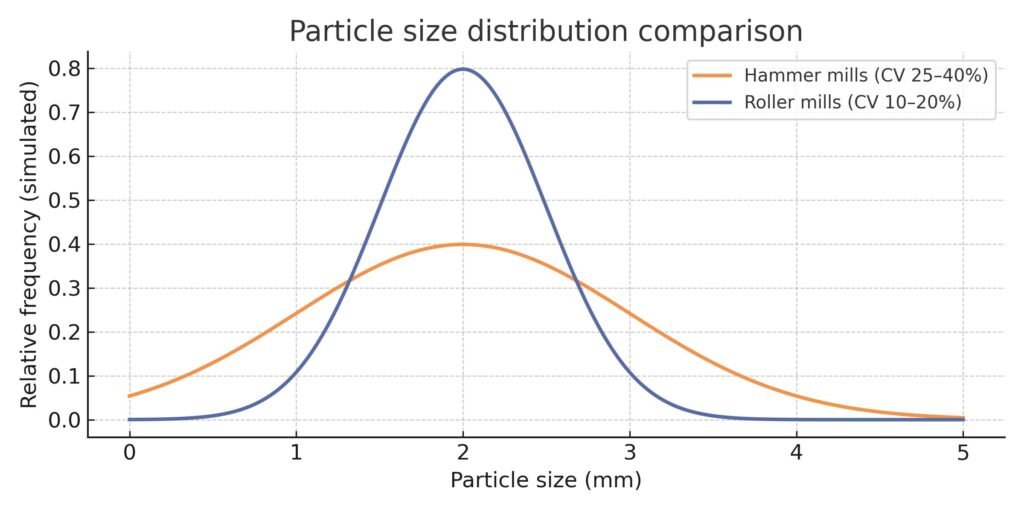

- In terms of particle size, roller mills offer precise control in the 0.1-5 mm range with coefficients of variation of 10-20%, while hammer mills provide a wider range of 0.5-10mm but with a wider dispersion (coefficient of variation 25-40%). This difference directly impacts the quality and uniformity of the final product.

- Operating costs favor roller mills, which have 20 to 30% lower maintenance costs annually. While hammer mills require component replacement every 200-500 hours of operation, roller mills extend these intervals to 2000-5000 hours, significantly reducing labor and replacement costs.

Physical principles and operation

Hammer Mill: Impact Technology

The operation of the hammer mill is based on the transformation of kinetic energy into fracture energy by direct impact. The rotor, equipped with fixed hammers, transfers kinetic energy to the material particles, which are fragmented by multiple simultaneous mechanisms.

The available kinetic energy is calculated by the formula E = ½mv², where the mass of the hammer (typically 0.5-2.5 kg) and the peripheral velocity determine the fragmentation capacity. With peripheral velocities ranging from 70 to 120 m/s, each hammer can generate impact energies in excess of 7500 J, sufficient to fracture materials with compressive strengths up to 150 MPa.

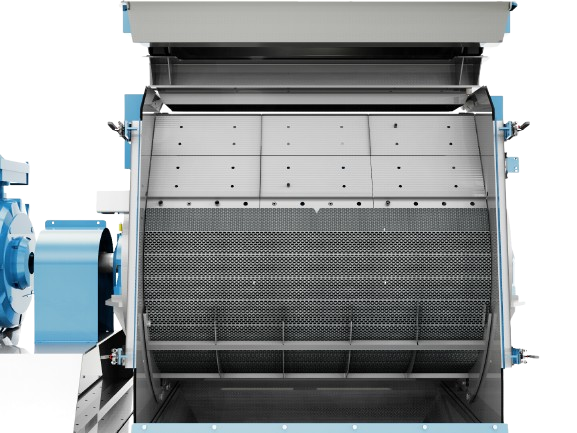

The grinding chamber incorporates screens with orifices ranging from 0.8 to 25mm depending on the desired particle size. The design of these screens directly influences the throughput rate and separation efficiency.

Fragmentation occurs by direct hammer-particle impact, particle-sieve impact, friction against the casing walls, and inter-particle collision. This multi-modal process results in a wide particle size distribution with significant fines generation.

Roller Mill: Compressive Technology

Roller mills employ progressive compression and shear forces between cylindrical surfaces to achieve size reduction. The material is introduced into the pressure zone between two rollers where it undergoes some deformation until it reaches the point of fracture.

The applied specific pressure is distributed over a contact surface that varies between 200-800mm in length, depending on the diameter of the rolls (typically 150-400mm). This uniform distribution of forces results in controlled fracture by directional cleavage, minimizing fines generation and preserving the structural integrity of the material.

Particle size control is achieved by precise adjustment of the roller gap, allowing variations of 0.1mm for fine grinding applications. Adjustment systems can be manual, hydraulic or pneumatic, with automatic wear compensation capability during operation.

Roller surfaces can be smooth, grooved or textured depending on the application. Grooves increase the material carrying capacity but increase wear, while smooth surfaces minimize abrasion but require higher contact pressure.

Energy efficiency and consumption

Energy efficiency represents a critical factor in the economic evaluation of grinding technologies. Hammer mills have specific consumptions of 10-16 kWh/ton for standard applications, scaling up to 25 kWh/ton when processing high hardness materials or looking for very fine granulometries.

Roller mills consistently produce more uniform particle sizes, with standard deviations 15–25% lower than impact systems.. This advantage is attributed to the directional application of compressive forces, which minimize the ventilation and turbulence losses characteristic of hammer mills.

The power factor also favors roller mills (0.90-0.95) over hammer mills (0.85-0.90), resulting from a more constant load and less fluctuation in energy demand. This feature reduces reactive power costs and improves the stability of the industrial power grid.

Thermal losses are another significant differentiator. Hammer mills generate temperature increases of 30-50°C in the product, whereas roller mills are limited to 10-20°C. This heating reduces nutritional quality in food applications and can affect the physical properties of heat-sensitive materials. In addition, less heat generation during milling also means less moisture loss from the product, which results in better physical quality of the feed. By conserving moisture, dust formation due to dry fines is reduced and caking in silos or hoppers is avoided, improving the fluidity and stability of the material throughout the storage and transport chain.

Overall mechanical performance puts roller mills at 85-92% versus 75-85% for hammer mills. Additional losses in impact systems are mainly due to forced ventilation required for dust evacuation and energy dissipated in vibration and noise.

For a plant processing 100 tons per day, the energy difference between the two systems can represent annual savings of €15,000-25,000, considering industrial electricity rates of €0.12/kWh.

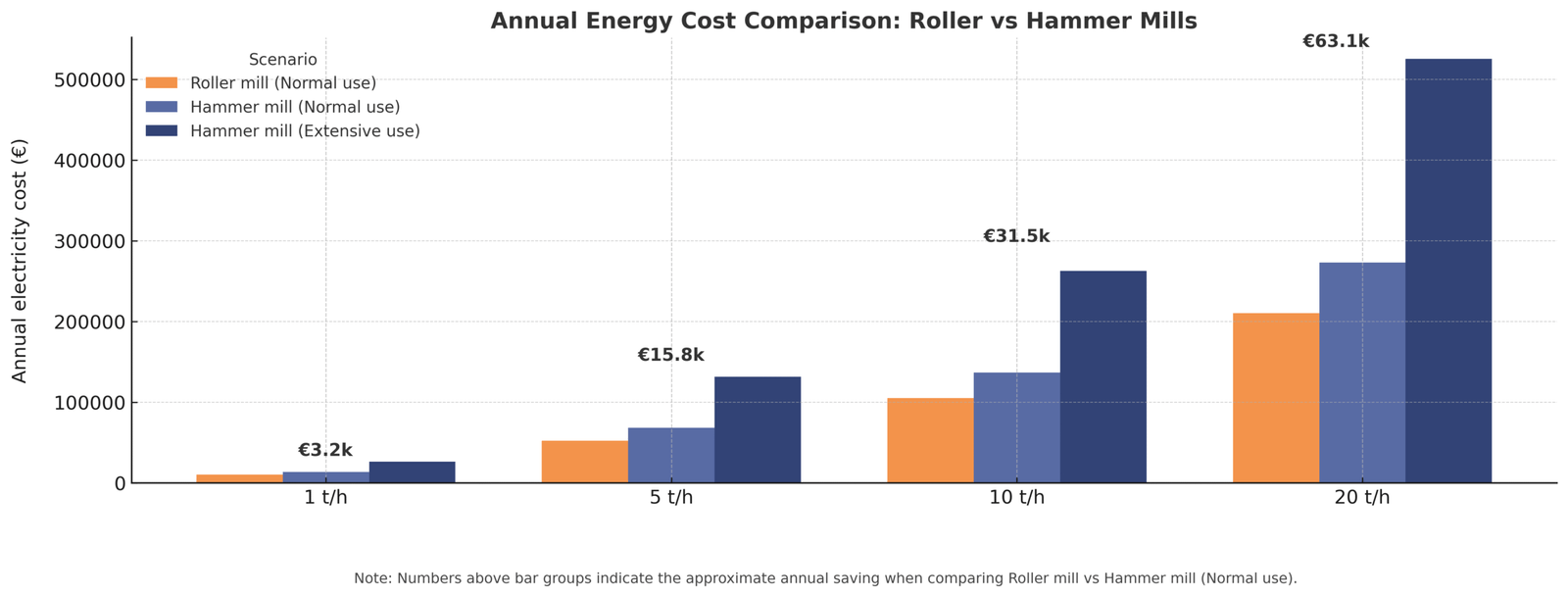

The following graph compares the annual cost of electricity between the two technologies for different production capacities (1, 5, 10 and 20 t/h), considering a continuous operation of 8,760 hours per year and a tariff of €0.12/kWh.

Taking this into account, we conclude the following:

-

Roller mills always show lower energy costs.

-

At 1 t/h, savings are around €3,200 per year.

-

At 5 t/h, savings grow to €15,800 per year.

-

At 10 t/h, the difference amounts to €31,600 per year.

-

At 20 t/h, savings exceed €63,000 per year.

-

-

The economic gap increases with plant capacity. The higher the throughput, the more the advantage of roller mills over hammer mills is amplified.

-

Energy savings (15-25%) are converted into direct economic savings. This benefit usually justifies the higher initial investment of roller mills in medium and large-scale industrial projects.

-

The intensive use of hammers (processing hard materials or searching for fine granulometries) increases consumption to 25 kWh/t, representing the worst case scenario and further accentuating the difference compared to rollers.

Granulometry ranges

Achievable particle size and accuracy are determining factors in the selection of grinding technology. Hammer mills provide a wide range of 0.5-10mm, with the ability to go down to 0.3mm through the use of fine screens and high rotor speed. However, this versatility is accompanied by a wide particle size distribution with coefficients of variation from 25-40%.

Roller mills offer significantly more precise particle size control in the 0.1-5mm range, achieving coefficients of variation of 10-20%. This accuracy results from the deterministic nature of the compression process, where the roller gap directly defines the maximum particle size.

The generation of fines represents a critical difference between the two technologies. Hammer mills produce 15-25% of particles smaller than 0.5mm, while roller mills are limited to 5-12%. This characteristic directly impacts the quality of the final product, especially in applications where fines affect flowability, stability or functional properties.

The ability to adjust particle size during operation clearly favors roller mills, which allow continuous modifications by means of hydraulic or pneumatic systems. Hammer mills require machine downtime for screen changes, resulting in production losses of 15-30 minutes per change.

The Pfost uniformity index, widely used in the feed industry, places roller mills in the range of 85-95% versus 70-85% for hammer mills. This parameter correlates directly with digestibility and feed conversion efficiency in monogastric species. A study with pigs showed that when corn was milled to ~400 µm, significantly higher nutrient digestibilities were achieved than when milled to ~800 µm.

For applications requiring multiple particle sizes, roller mills offer superior operational flexibility, while hammer mills are more suitable when robust processing of heterogeneous materials with tolerance to particle size variations is required.

Operating costs

Maintenance costs

Maintenance costs represent a significant proportion of operating expenses for grinding equipment. Hammer mills require annual investments of €3,000-8,000 per ton/hour of installed capacity, while roller mills range from €2,000-5,500 for equivalent capacity ranges.

The frequency of replacement of critical components makes a substantial difference between the two technologies. Hammers require replacement every 200-500 hours of operation, depending on the abrasiveness of the material being processed and the hardness of the wear elements. In contrast, rollers extend their service life to 2000-5000 hours, significantly reducing downtime and associated labor.

However, the five-year total cost of ownership (TCO) analysis shows consistent advantages for roller mills. Lower maintenance frequency reduces skilled labor costs, minimizes production losses due to scheduled shutdowns, and decreases required spare parts inventories.

Energy Costs

Energy costs are the most significant operating component in high capacity applications. At industrial rates of €0.12/kWh, hammer mills generate costs of €12-20 per ton processed, while roller mills are €9-15 per ton for comparable applications.

The amortization of the energy differential allows the higher initial investment of roller mills to be recovered in periods of 2-4 years, depending on annual operating hours and installed capacity. For plants with continuous operation (>6,000 hours per year), the payback period is often reduced to less than 24 months.

Government incentives for energy efficiency can significantly accelerate the economic justification for roller mills. Energy saving programs in European countries offer tax deductions of 20-40% for equipment demonstrating consumption reductions greater than 15%.

Maintenance requirements

Hammer Mills

Hammer mill maintenance requires a rigorous predictive approach due to accelerated wear of critical components. Weekly hammer inspection should include residual thickness measurement, fastener verification and fatigue crack detection. Hammers with wear in excess of 30% of nominal thickness require immediate replacement to avoid dynamic imbalance.

In addition, it is important to consider changing the direction of rotor rotation in hammer mills, a practice that helps to balance hammer wear and prolong equipment life. This periodic change allows impact forces to be more evenly distributed over the hammer and screen surfaces, reducing fatigue and improving overall mill performance.

Preventive maintenance includes scheduled hammer changes every 200-500 hours, depending on the abrasiveness factor of the material being processed. Materials with abrasiveness index above 150 mg (ASTM G65 test) reduce service life to 200-300 hours, while products with low mineral content can extend intervals to 500-800 hours.

Dynamic balancing of the rotor is a critical operation every 1,000 hours to prevent excessive vibrations from compromising the structural integrity of the equipment. Unbalances greater than 6.3 mm/s (ISO 10816) require immediate correction by redistributing the hammers or adding counterweights.

Roller Mills

Roller mills require predictive maintenance focused on gap and surface wear control. Measurements every 500 hours should include roller parallelism checks (tolerance ±0.1mm), diametral wear measurement, and vibration analysis to detect possible misalignment.

Readjustment of the rollers to compensate for wear is performed every 200 hours of operation, using hydraulic or mechanical systems depending on the design of the equipment. This process requires precise calibration to maintain the specific pressure within the operating ranges (50-200 N/mm²) and to ensure uniform load distribution.

Roller liners are scheduled for renewal every 2,000-5,000 hours depending on the material being processed. Hardened steel liners provide greater wear resistance but increase costs, while special alloys (tungsten carbide, ceramics) extend service life up to 8,000 hours in extreme applications.

Specialized personnel require specific training, with intervention times of 4-8 hours per maintenance operation. The complexity of the adjustment systems requires advanced knowledge in oleo hydraulics and precision instrumentation.

Technical advantages and limitations

Hammer Mills

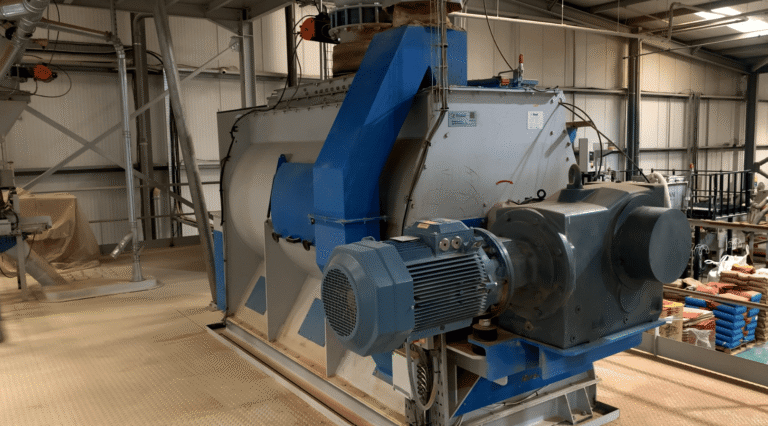

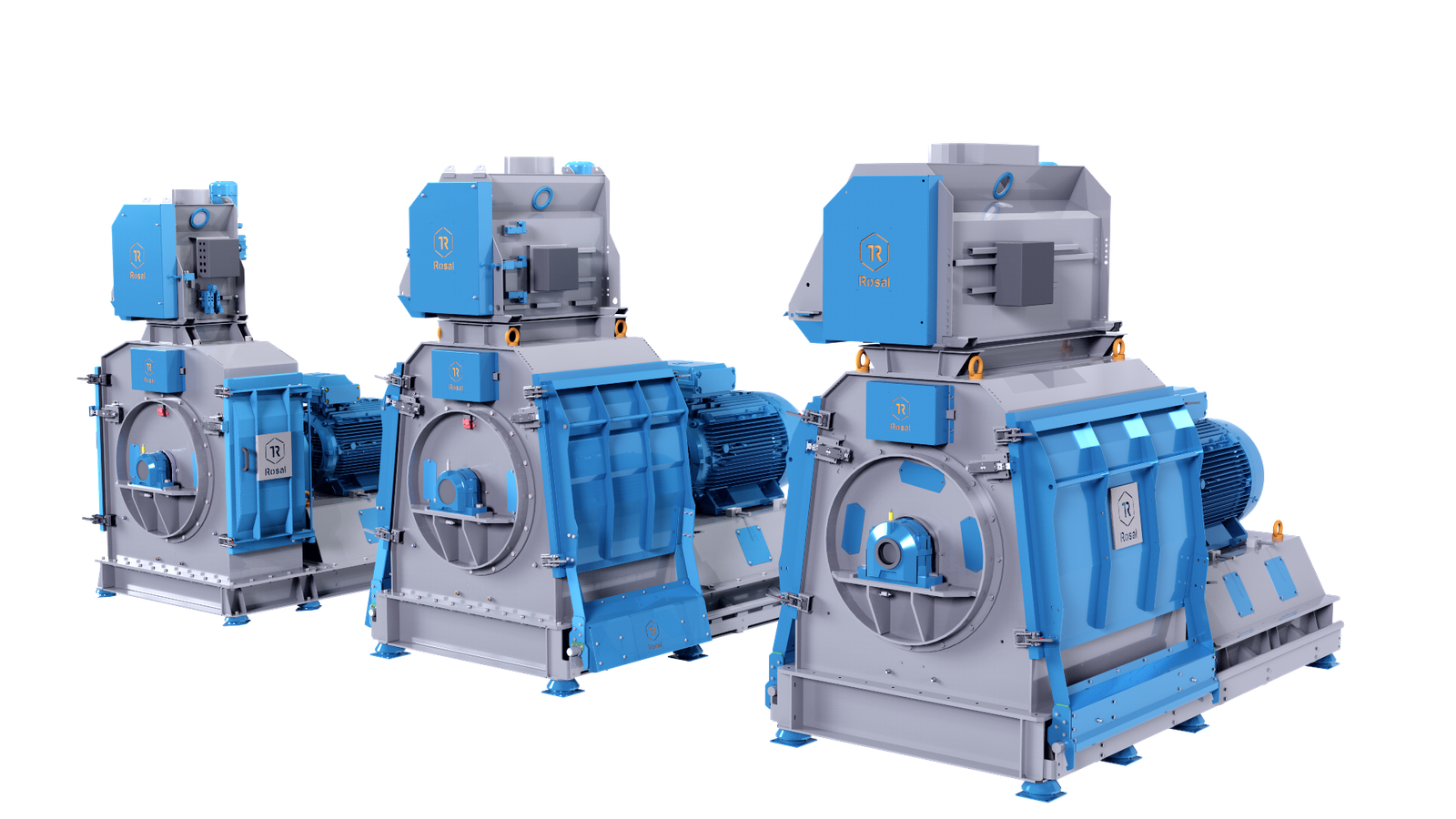

Hammer mills have exceptional versatility for processing heterogeneous materials with variations in hardness, moisture and composition. The robust design allows them to tolerate occasional metal contaminants without causing catastrophic damage, a feature especially valuable in recycling and agricultural by-product processing applications.

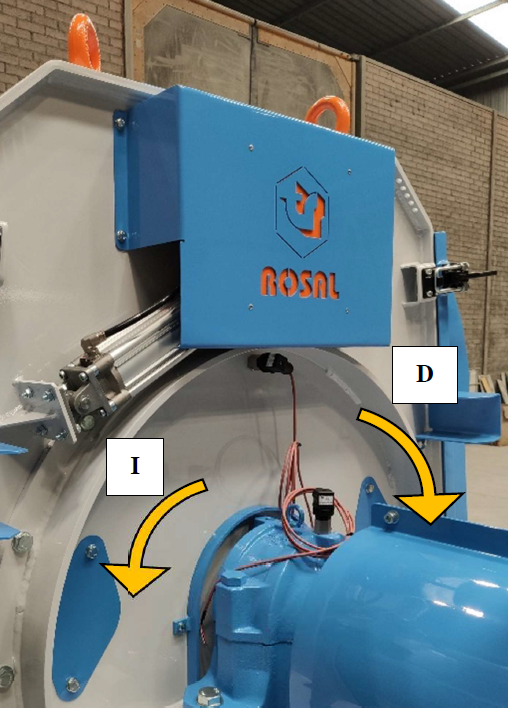

Relatively low initial investment facilitates adoption in operations with budget constraints. The ease of operation allows quick change of product particle size by replacing screens. This process is especially fast on the MMR Rosal hammer mills, which feature side doors that allow quick and safe access to the grinding chamber, and therefore to the screens. In less than 30 minutes it is possible to change the screens of the mills with this system.

Processing capacity ranges widely from 1-50 t/h in standard configurations, with special designs reaching up to 200 t/h for biomass and recycling applications. This scalability facilitates adaptation to different production volumes without major process modifications.

Limitations include higher energy consumption, especially problematic in fine grinding applications where efficiency can drop to 60-70%. Excessive fines generation (15-25%) affects product quality in applications where particle size uniformity is strict.

Operating noise of 85-95 dB(A) requires noise control measures and hearing protection for personnel, increasing infrastructure and compliance costs. Product heating (30-50°C) can degrade thermosensitive components such as vitamins, enzymes and aromatic compounds.

Roller Mills

The roller mills feature superior energy efficiency, achieving 15-25% consumption reductions that translate into significant long-term operational savings. Precise particle size control (10-20% coefficient of variation) is ideal for applications requiring tight particle size specifications.

Quiet operation (70-80 dB(A)) eliminates the need to acoustically treat the surroundings and improves working conditions. Lower product heating (10-20°C) preserves nutritional and organoleptic properties, especially critical in premium food applications.

Minimal dust generation simplifies dust extraction systems and reduces explosion risks in combustible materials. Extended maintenance intervals (2,000-5,000 hours) minimize production downtime and skilled labor costs.

The main limitation is the high initial investment (€25,000-80,000 for equivalent capacities), which may exceed available capital budgets. Sensitivity to foreign materials requires effective pre-cleaning systems, increasing the complexity of the process.

Limitations in fibrous materials restrict applications in processing biomass and agricultural by-products with high cellulose content. Feeding must be uniform and calibrated, requiring precise dosing systems that increase installation costs.

Applications by sector

Food Sector

In the food industry, the selection between a hammer mill or a roller mill is mainly determined by the quality requirements and the characteristics of the processed material. Hammer mills are especially optimal for processing spices, crystallized sugar, dehydrated products and condiments, where significant size reduction with tolerance to particle size variations is required.

Typical capacities for food applications range from 0.5-10 t/h for hammer mills, adapting to artisanal and semi-industrial production. Ease of cleaning and fast changeover between products is advantageous in multi-product operations with small batches.

Roller mills dominate the production of refined flours, brewing malts and processed cereals, where grain size uniformity directly determines the quality of the final product. Commercial capacities reach 2-25 t/h, with special installations exceeding 100 t/h for large flour mills.

FDA 21CFR178 compliance favors roller mills due to lower cross contamination and ease of sanitization. Preservation of nutritional properties by lower heating is critical in premium and organic products, where thermal degradation affects commercial value.

Food traceability is facilitated with roller mills due to less dust generation and better process control. Continuous monitoring systems allow documentation of critical control parameters (pressure, temperature, particle size) required by standards such as HACCP and BRC.

Feed Sector

The feed industry represents one of the most dynamic markets for both grinding technologies. Hammer mills maintain their predominance in the processing of fibrous raw materials, agricultural by-products and pre-grinding operations, where robustness and operational flexibility justify the higher energy costs.

Installed capacities in feed production plants typically range from 1-30 t/h for hammer mills, scaling up to 50 t/h in high-capacity installations. Moisture tolerance (8-15%) is advantageous when processing seasonal raw materials with varying water content.

Roller mills are increasingly used in the final milling of major cereals (corn, wheat, barley), where the improved digestibility of the 8-15% directly impacts feed conversion efficiency. Commercial capacities reach 3-50 t/h, with a trend towards larger scale installations.

The improved FCR (Feed Conversion Ratio) of the 3-7% with the roller mills justifies a major investment in large-scale operations. For a 100,000 fattening pig farm, this improvement represents an annual savings of €150,000-300,000 in feed costs.

Reducing dust in rations improves on-farm environmental conditions and reduces handling losses. Roller mills generate 40% to 60% less dust than impingement systems, contributing to animal respiratory health and the efficiency of automated feeding systems.

Biomass Sector

The biomass processing presents unique challenges that favor different technologies depending on the type of material. Hammer mills dominate the processing of wood chips, forest residues and rejected pellets, where the ability to handle fibrous and heterogeneous materials is critical.

The moisture tolerance of the 8-15% allows biomass with varying water contents to be processed without significant yield degradation. Typical capacities range from 2-20 t/h for biomass applications, with special designs reaching 50 t/h for large-scale installations.

Roller mills find application in processing energy grains, dry agricultural residues and pre-densification operations. Moisture limitation (<12%) requires pre-drying systems that increase operating costs but improve overall energy efficiency.

Optimum combustion size (<3mm according to EN 14961) is achievable by both technologies, although roller mills provide greater uniformity which improves combustion efficiency and reduces particulate emissions.

Preparation for pelletizing favors hammer mills due to the higher specific surface area generated by intensive fragmentation. The 20-30% increase in specific surface area improves cohesion during the pelletizing process and final pellet density.

In biomass processing it is common to combine hammer mills and roller mills within the same grinding line. Hammers are used in the pre-grinding stage, where they reduce the size of fibrous materials or materials with variable moisture, while rollers perform the finish grinding, obtaining a more uniform particle size suitable for pelletizing.

This combination improves overall energy efficiency, reduces dust generation and preserves product moisture, resulting in higher density and quality of the final pellet.

Below is a summary table with the recommendation of the most suitable type of grinding technology according to the industry sector and the specific application. This technical comparison allows quick identification of which system - hammer mill or roller mill - offers the best performance depending on the type of material, particle size requirements, production capacity and operational objectives.

| Application / Sector | Typical material | Production range | Milling target | Recommended | Technical justification |

|---|---|---|---|---|---|

| Feed for monogastric animals | Corn, wheat, barley, soybean | Medium-High (10-40 t/h) | High digestibility, uniform granulometry | Roller mill | Lower particle size deviation (Pfost > 90 %), less fines and better FCR |

| Ruminant feed | Fibrous mixtures, dry hay, cereals, cereal grains | Medium (5-20 t/h) | Basic reduction without spraying | Hammer mill | Better tolerance to long fiber and moderate humidity |

| Biomass (pellets, fuels) | Chips, shavings, prunings, dry residues | Medium-Low (2-10 t/h) | Breakage prior to pelletizing | Hammer mill | High tolerance to hard bodies and humidity variations |

| Flours for human consumption | Soft wheat, rye, oats | Medium-High (10-30 t/h) | Controlled cutting and homogeneous grinding | Roller mill | Greater size control and lower process temperature |

| Extrusion / animal pelletizing | Preconditioned feed flour | High (20-50 t/h) | Final milling before extrusion | Roller mill | Less fines generation, better compaction afterwards |

| Chemical / pharmaceutical industries | Soft minerals, excipients | Low (0.5-5 t/h) | Precise particle size and thermal control | Roller mill | Superior energy efficiency, thermal control and minimal particle size dispersion |

Quality of the final product

Final product quality is often the determining factor in the selection of grinding technology. Roller mills demonstrate consistent superiority in particle size uniformity, achieving 15-25% standard deviations lower than impact systems. This uniformity directly impacts product functionality in downstream applications.

Particle morphology significantly differentiates the two technologies. Roller mills generate particles with more regular shapes and smooth surfaces, while hammer mills produce angular particles with irregular surfaces. This difference affects the flow, compaction and dissolution properties of the final product.

In cereal applications, roller mills preserve gelatinizable starch better (95% vs. 85% in hammer mills), maintaining critical functional properties for baking and further processing. Controlled fragmentation minimizes structural damage to starch granules and proteins.

Thermal contamination is a critical concern in thermosensitive products. Hammer mills can degrade 5-10% of thermolabile vitamins due to frictional heating, while roller mills limit this degradation to 1-3%. In pharmaceutical and nutraceutical applications, this difference can determine the commercial viability of the product.

The specific surface area generated favors hammer mills, which produce 20-30% increases over rollers. This feature is advantageous in applications where dissolution rate or chemical reactivity are critical performance factors.

Particle size segregation during handling and storage is minimized with roller mill products due to the narrower size distribution. Segregation reduction improves homogeneity of blends and dosing consistency in automated processes.

Operational flexibility

Operational flexibility refers to the ability of milling systems to adapt to changes in raw materials, product specifications or demand.

Hammer mills are notable for allowing rapid particle size adjustments in as little as 15 to 30 minutes by replacing screens. This makes them particularly useful for small batches or for handling a wide variety of products.

On the other hand, roller mills can change the particle size during operation thanks to hydraulic or pneumatic systems, which avoids downtime. However, this process requires more specialized personnel.

In terms of working ranges, hammer mills operate well between 20% and 120% of their rated capacity, while roller mills operate well between 40% and 110%, although they have more limitations at the extremes of operation.

In terms of materials, hammer mills are more versatile: they can process between 15 and 20 different types, tolerating variations in humidity and the presence of contaminants. Roller mills, on the other hand, require more uniform and dry raw materials. In addition, hammer mills can start up immediately, while roller mills require 5 to 10 minutes of warm-up time.

Both systems are compatible with automation, although rollers offer greater precision and standardization. They are therefore more suitable for continuous and scalable processes, while hammers are valued for their robustness and ability to work with difficult materials.

Final conclusions

The choice between a hammer mill and a roller mill will depend on multiple factors specific to the production process, such as the type of material to be ground, the required capacity, operating costs and the desired characteristics of the final product. Both systems have advantages and limitations that make them more suitable for certain applications and conditions. The following summary table highlights the main differences and key aspects of each technology to support a more accurate, informed evaluation.

| Appearance | Hammer Mill | Roller Mill |

|---|---|---|

| Principle of operation | Direct impact with rotary hammers | Compression and shearing between rollers |

| Operating speed | High (1500-3600 rpm) | Low (100-300 rpm) |

| Energy consumption | 10-16 kWh/tonne, up to 25 kWh/tonne | 8-12 kWh/ton (15-25% less than hammers) |

| Grain size control | Range 0.5-10 mm, coefficient of variation 25-40% | Range 0.1-5 mm, coefficient of variation 10-20% |

| Fines generation | High (15-25% particles <0.5 mm) | Low (5-12% particles <0.5 mm) |

| Maintenance costs | More frequent, hammer replacement every 200-500 hours | Less frequent, maintenance every 2000-5000 hours |

| Temperature generated | 30-50°C increase | 10-20°C increase |

| Operating noise | High (85-95 dB(A)) | Low (70-80 dB(A)) |

| Adjustment flexibility | Quick screen change (15-30 minutes) | Continuous non-stop hydraulic/pneumatic adjustment |

| Typical applications | Fibrous materials, biomass, recycling | Large-scale production, food, minerals |

| Initial investment | Relatively low (€15,000-50,000) | Higher (€25,000-80,000) |

| Advantages | Versatile, robust, quick adjustment | Energy efficient, precise control |

| Limitations | Higher energy consumption, more fines generated | Sensitive to foreign materials, high investment |

Frequently Asked Questions (FAQ)

What is the main difference between a hammer mill and a roller mill?

The hammer mill crushes the material by rapid and strong blows with rotating hammers, while the roller mill crushes the material by compressing and crushing it between two slowly rotating rollers.

Which mill consumes less energy?

The roller mill is more energy efficient, consuming between 15% and 25% less energy than the hammer mill, which can translate into significant production savings.

Which mill produces a more uniform particle size?

The roller mill offers more precise particle size control, achieving a more uniform particle size with fewer very small particles (fines).

Which mill is best for fibrous or high moisture materials?

The hammer mill is more suitable for fibrous materials and materials with variable moisture, as it can better handle these characteristics without damage.

Which is noisier and generates more heat?

The hammer mill generates more noise (85-95 dB) and raises the product temperature more than the roller mill, which can affect the quality of certain heat-sensitive materials.

Which one is easier and less frequent to maintain?

The roller mill requires less maintenance and its components last longer, while the hammer mill needs to replace the hammers more frequently.

Which mill is more flexible in changing the grind size?

The hammer mill allows the particle size to be changed quickly by changing screens, while the roller mill can adjust the size without stopping the machine, but requires more specialized personnel.

What is the highest initial investment?

Generally, the roller mill has a higher initial investment than the hammer mill, although in the long term it can be more profitable due to its efficiency and lower maintenance.

In which industries are these mills most commonly used?

Hammer mills are common in industries processing biomass, recycling and animal feed, while roller mills are preferred in the production of flour, processed foods and minerals.

How does the choice of mill affect the environment?

The roller mill generates less dust, noise and heat, contributing to a healthier working environment and less environmental impact compared to the hammer mill.