Machinery

We design, manufacture, and assemble feed mill machinery for every stage of the production process.

We use the best qualities of steel (carbon steel, stainless steel or galvanized steel), in addition to assembling top brands in both drive units and components.

The robustness of the materials and the quality of the components/accessories, together with the necessary preventive maintenance, guarantee a long service life of our machinery.

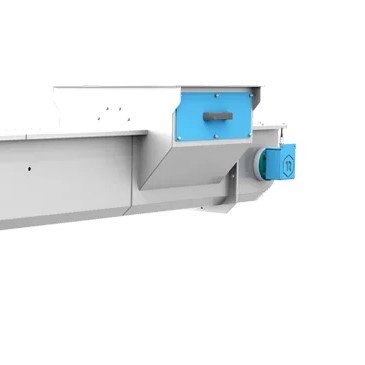

Chain conveyor

The chain conveyor is ideal for covering long lengths and for the extraction of the product from underneath the hoppers.

Screw conveyor

Screw conveyors are equipment designed to transport products horizontally or vertically.

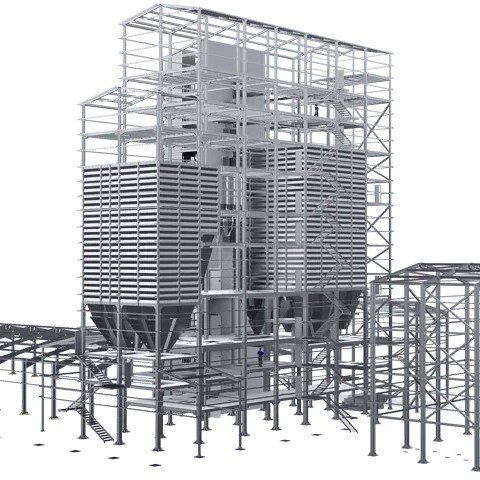

Grain silos

Our silos are designed to offer efficient and safe storage solutions for bulk products.

Steel structures

Metal structures designed to support the weight of the entire storage system of a feed mill.

Grain cleaner

Pre-cleaners are designed to protect manufacturing equipment from wood chips, stones and other particles.

Flour sifter

The sifter filters and separates foreign agents such as iron, stones or cardboard from the flours.

Rotary screen

Rotary screens are used to separate fines from pellets in different sizes and capacities.

Roller mill

The roller mill is ideal for installations that require homogeneous grinding with a minimum percentage of fines.

Flaking mill

The flaking mill produces cereal flakes, ideal for livestock due to their excellent digestibility.

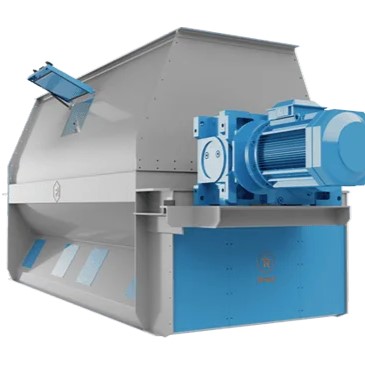

Ribbon and paddle mixers

Ribbon or single shaft paddle mixers ensure effective homogenization.

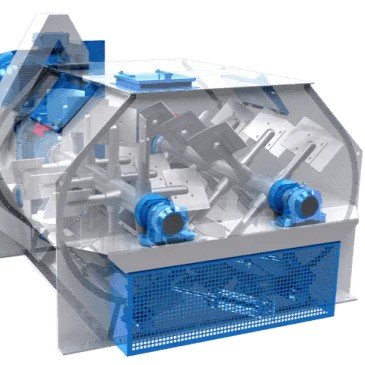

Twin shaft paddle mixer

The twin rotor mixer is ideal for mixing products with very different textures, such as pellets, flours and extrudates.

Turbulence mixer

The vertical mixer achieves optimum homogenization levels without deteriorating the product.

Dosing units

The dosing phase in feed mills is key to ensure accuracy in the mixing of vitamins and additives.

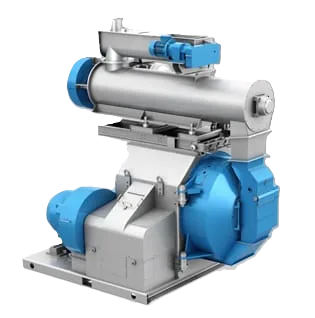

Pellet mill

Mabrik industrial pellet mills are built with high quality materials and great robustness.

Pellet conditioner

Conditioners generate the heat treatment necessary to prepare the product prior to pelletizing.

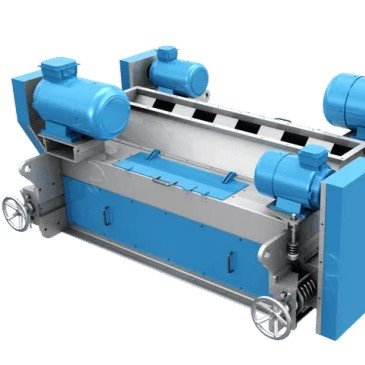

Counterflow cooler

Mabrik counterflow coolers are designed to cool the pellets coming out of the pelletizing process.

Hygieniser

The hygieniser is designed to reduce and eliminate pathogens in compound feed.

Coater

Coaters are equipment designed to optimize the final quality of the feed, allowing the precise addition of fat.

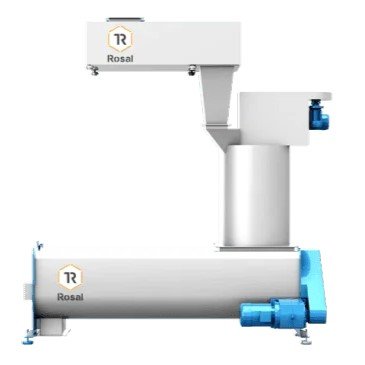

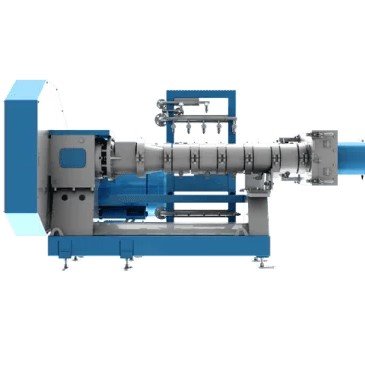

Extruder

The Rosal extruder is designed to manufacture high quality extruded food for dogs, cats, fish and cereals.

Belt dryer

The belt dryer is designed to provide uniform feeding, which ensures a balanced drying of the product.

Drum dryer

The rotary drum dryer achieves minimum moisture content in the final product.