PELLETING

Mabrik Pellet Mills

Mabrik industrial pellet mills are built with high quality materials and great robustness.

Its design incorporates high dynamic and static load bearings that allow it to work with maximum reliability and in the toughest conditions, such as the pelleting of alfalfa, by-products, residues, wood, etc.

Features

Models

Pellet mill models

Thinking of all possible pelleting fields, Mabrik has created different lines of pellet mills:

- PVB Models:Pellet mills with motor on the baseplate are models with high rigidity and particularly smooth operation due to their rubber insulation. These pellet mills are the most advanced models and are especially recommended for pelleting difficult products.

- PVR models: Pellet mills with a compact design with the motor located at the top, ideal for installation in confined spaces.

Design

Rollers and transmission

- Rollers:Depending on the product to be pelletized, the pellet mill can be configured with 2 or 3 manually adjustable rollers or with an automatic roller adjustment system "RA".

- Transmission: To adapt to the most suitable tangential speed for the product to be pelletized, we have different combinations of V-belt transmissions. We use the latest generation of V-belts achieving transmission efficiencies up to 98% and minimum maintenance.

Spare parts

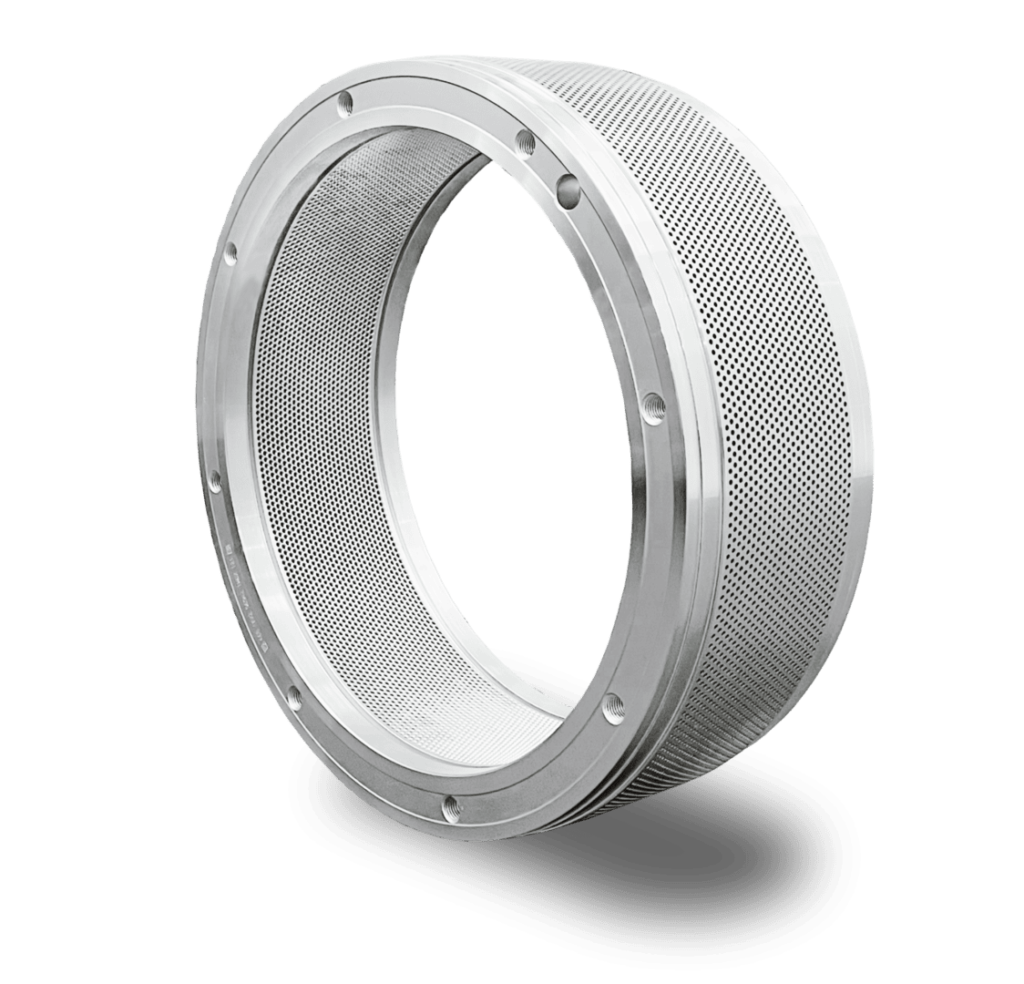

Matrices

Mabrik also specializes in the production of dies, built with the best quality steels and using the most modern technology for their execution, heat treatment and finishing. Dies are manufactured for all types of pellet mills, using case hardening steel and stainless steel, bores of different diameters -from 1.8 to 25 mm- and special shapes (squares, cookies, among many others).

Models

Thinking of all possible pelletizing fields, Mabrik has created different lines of pelletizers:

| Model | Inner die diameter (mm) | Pellet diameter (mm) | Motor power (kW) | Estimated production (Tn/h) |

|---|---|---|---|---|

| PVR 40 | 280 | 2 - 4 | 30 | 1 - 3 |

| PVR 100 | 354 | 2 - 5 | 75 | 3 - 8 |

| PVR 150 | 452 | 2 - 5 | 110 | 4 - 12 |

| PVR 180 | 550 | 2 - 5 | 132 | 5 - 14 |

| PVR 220 | 650 | 2 - 8 | 160 | 6 - 17 |

| PVR 270 | 750 | 2 - 8 | 200 | 8 - 21 |

| PVR 360 | 850 | 4 - 10 | 250 | 12 - 28 |

| PVR 440 | 950 | 4 - 10 | 315 | 14 - 35 |

| PVR 750 | 1100 | 4 - 10 | 560 | 22 - 60 |

Frequently Asked Questions

Mabrik offers pelletizers suitable for biomass, animal feed, solid waste and organic fertilizers, processing wood, sawdust, manure, agricultural residues and other materials with different moisture levels and particle sizes.

The body of the Mabrik pelletizers is made of treated carbon steel, while the hopper, door and pelletizing chamber are made of AISI 304 stainless steel, which guarantees high resistance and durability to corrosion and even abrasive materials.

The rollers are adjusted by means of a regulating screw with locking nuts and self-locking system, without the need to disassemble the cap funnel. This allows precise and fast adjustment by a single operator.

They incorporate multiple safety devices: limit switches, microswitches, improper opening detectors, adjustable mechanical clutch and special clutch for sudden loads, all designed to stop the machine automatically in case of failure or unauthorized opening.

The system automatically and continuously lubricates the rollers and bearings of the main shaft without the need for manual intervention. For this purpose, it uses a centralized mechanism consisting of a 5 or 10 kg reservoir, a progressive distributor with fault detection and a start-up synchronized with the main motor.

Mabrik pelletizers use V-belts in the primary and secondary drive. These reduce vibrations and facilitate maintenance, while offering a quieter and safer transmission against overloads thanks to the "belt saver" type rotation detector.

Special wrenches are included for: die setting, roller adjustment, locking nuts, flange tightening and main shaft safety adjustment, allowing fast and safe maintenance.

Optionally, a motorized lifting system can be installed or a quick-change forklift can be incorporated, which optimizes downtime and significantly reduces the operator's physical effort.

The pressure is adjusted by the individually adjustable roller system, which applies constant and uniform force. The mechanical clutch protects the die against overloads, prolonging its service life.

Request more information

Leave us your details and questions and a Mabrik pellet mill technician will advise you without obligation. Let's talk!

Related machinery

Pellet conditioner

Conditioners generate the heat treatment necessary to prepare the product prior to pelletizing.

Counterflow cooler

Mabrik counterflow coolers are designed to cool the pellets coming out of the pelletizing process.

Hygieniser

The sanitizer is designed to reduce and eliminate pathogens in the compound feed.

Coater

Regreasers are equipment designed to optimize the final quality of the feed, allowing the precise addition of fat, oil or other liquids to the pellet.