Alltech, a global company specializing in animal nutrition, has entrusted Rosal with the design and supply of a new premix line at its plant in the United Kingdom.

The project, internally named Titan, marks a significant advance in the search for efficiency, cleanliness and flexibility in animal feed production.

The challenge: improving process efficiency and safety

With production facilities in Europe, the Americas, Asia-Pacific and the Middle East, Alltech manufactures most of its products in-house, ensuring total control over quality.

In its Stamford (Lincolnshire), the company was looking for a solution that would allow it to handle and mix powdered products safely, homogeneously and efficiently, reducing dust emission and adapting to different formulations.

Until then, Alltech had worked with several different suppliers of individual equipment - mixers, conveyors and packaging systems - but needed a manufacturer of industrial machinery capable of offering a complete line of industrial machineryThe project is tailored to your technical, space and time requirements.

The solution: engineering and industrial machinery from Rosal

After evaluating several proposals, Alltech chose Rosal for its technical capability, reliability and ease of communication with the plant's engineering teams.

Rosal designed and delivered a integral powder mixing lineThe company's product range combines efficiency, safety and quality of the final product.

The installation includes:

-

A manual unloading station for raw materials.

-

Pneumatic conveying to the mixer.

-

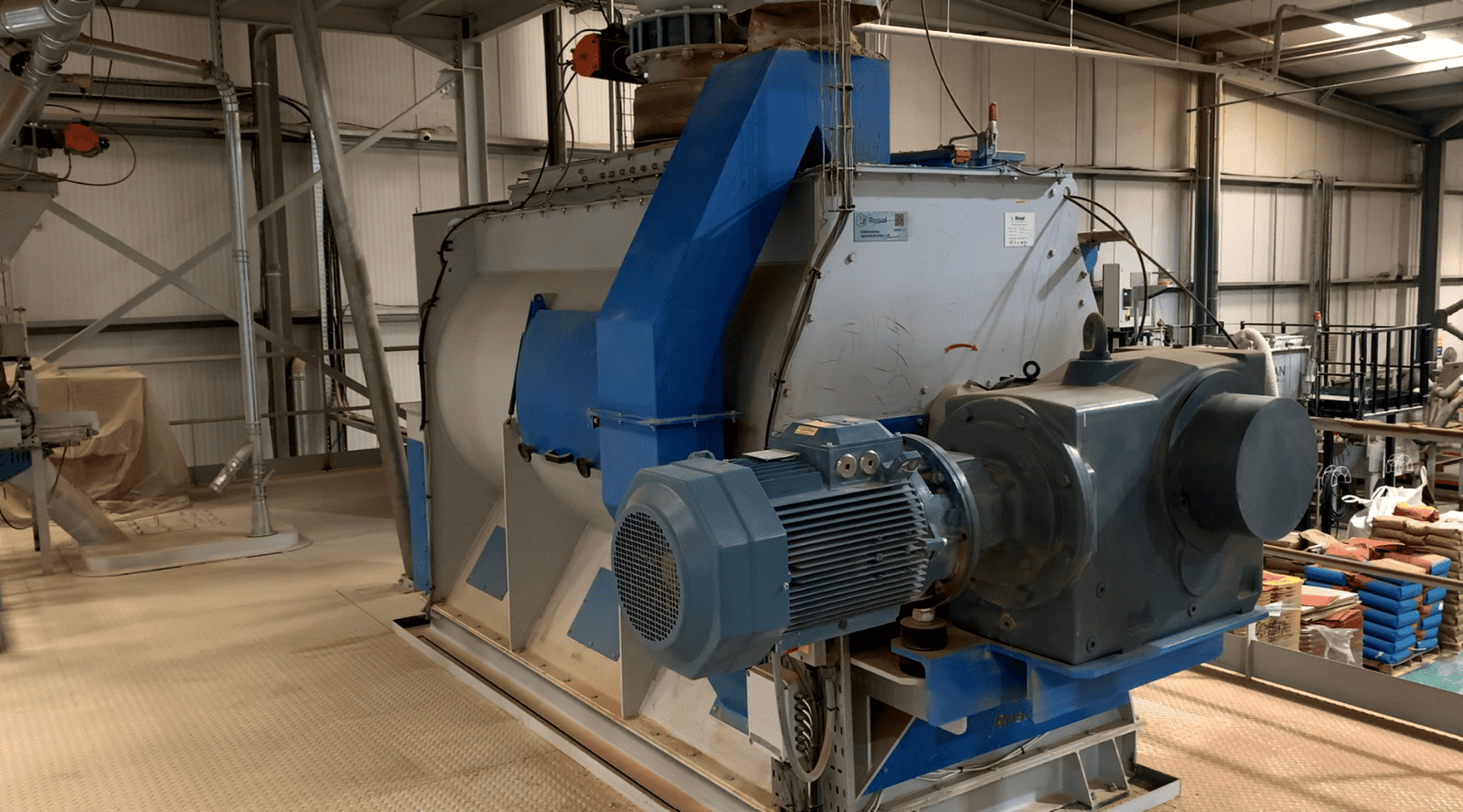

A paddle mixer which guarantees a homogeneous mix.

-

A bagging line for the finished product.

-

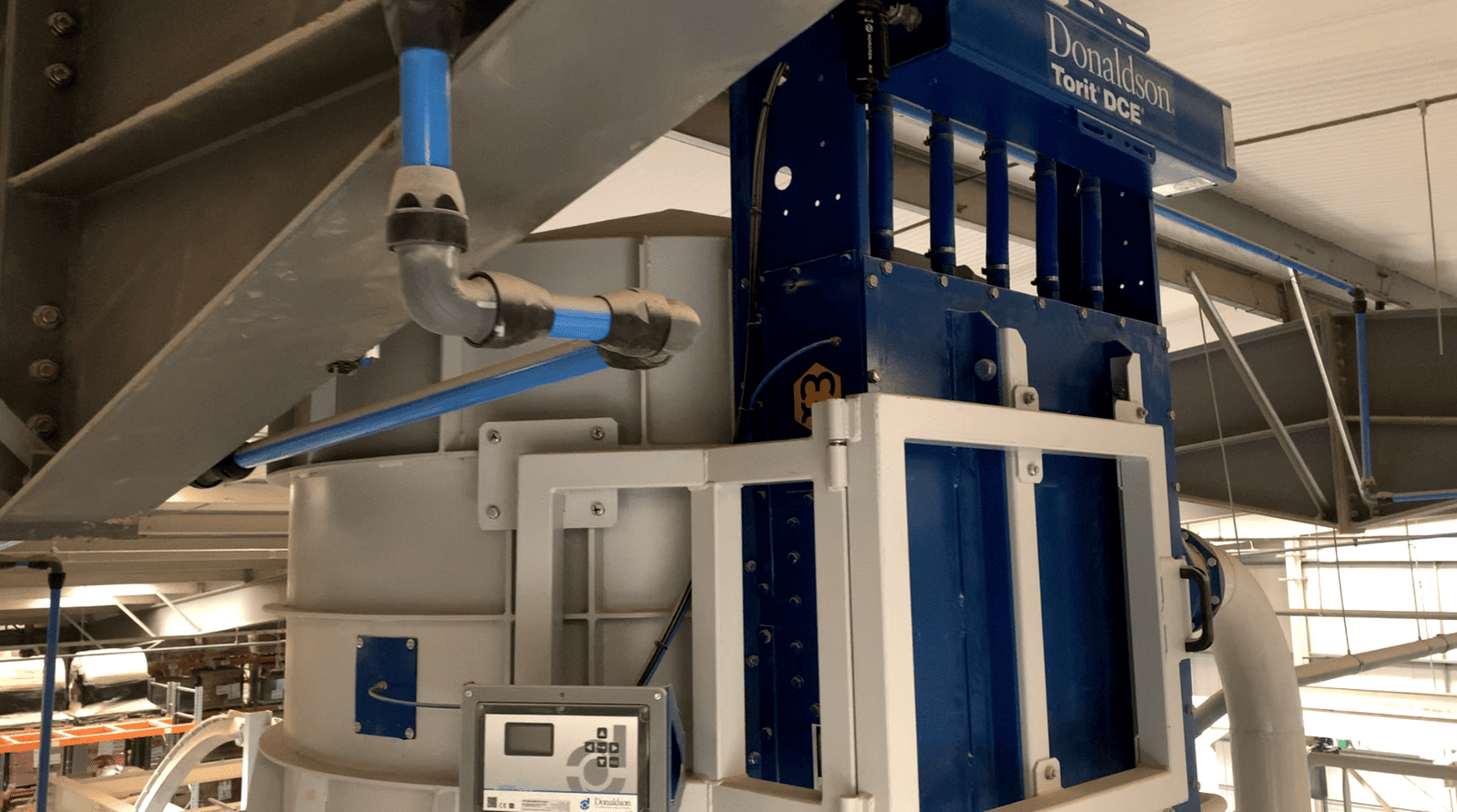

And a central dust extraction system, which maintains a clean and safe working environment.

Thanks to this set of equipment, Alltech has achieved a greater capacity to adapt to the needs of its customers, both in terms of formulations and types and sizes of packaging.

Hal Davis (COO of Alltech): "Rosal delivered on time, quality and communication".

During the interview conducted by Rosal, Hal Davis, operations director of Alltech, emphasized the value of collaboration:

With the new line, we have gained flexibility. We can offer customized solutions to our customers, adapting the products to their needs.

We chose Rosal because they understood our space and time constraints, and because communication was excellent at all times. They were on time, on budget and did not interfere with the rest of the plant.

You can see the full interview with Hal Davis below:

Results: a more flexible, cleaner and more efficient plant

Collaboration between Alltech and Rosal has made it possible to start up a blending line that offers:

-

Greater flexibility to manufacture different types and formats of premixes.

-

Homogeneous mixtures and high quality end products.

-

Dust reduction and improving safety in the work environment.

-

Cleaner and more efficient processesin compliance with industrial hygiene and safety regulations.

Conclusion: industrial machinery at the service of animal nutrition

The joint project between Alltech and Rosal demonstrates how the experience in design and manufacture of industrial machinery can transform the production processes in the food processing sector. animal nutrition.

With this new facility, Alltech strengthens its ability to offer high quality products, while Rosal consolidates its position as a leading supplier of a leader in the design and supply of equipment for premix and feed production..