Feed extrusion has established itself as one of the most efficient and widespread technologies for producing high quality feed.

This process not only improves digestibility and the nutritional valuebut also optimizes the texture, palatability y stability of pet food, poultry, fish and livestock feed.

As a result, extrusion contributes directly to animal health and productive performance.

The extrusion process step by step

The extrusion process in animal feed can be divided into four fundamental phases:

1. Feeder

The extruder must be constantly fed by means of volumetric dosing units or small tanks. This ensures a continuous flow of ingredients.

2. Conditioning

The product needs to be pre-conditioned to wet it and plasticize it before entering the extruder. To achieve this, between 2% and 4% of steam is added depending on the amount of product to be treated.

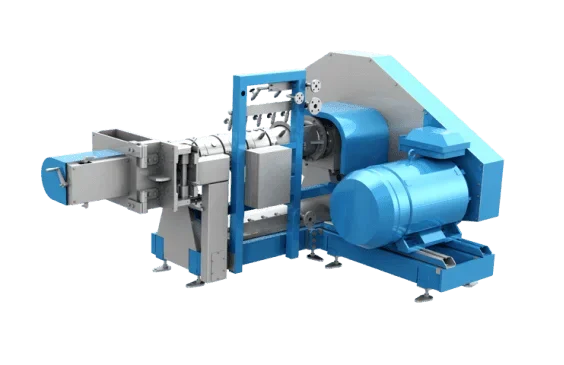

3. Extrusion

The following are mainly used in animal feed extruders single-spindle machines, as they are more economical and energy-efficient.

Inside the extruder, the process is divided into three stages:

a) Entry section

A worm screw moves the ingredients forward while mixing and compressing them progressively.

b) Heat and pressure cooking

The spindle narrows along the barrel, which causes a higher internal pressure on the mixture. This friction raises the temperature of the dough, cooking it evenly.

The temperature is raised in two ways: by friction, or by combining friction with additional heat, either by heating the extruder barrel or by injecting steam directly.

c) Molding and expansion

Upon exiting the matrix, the material passes from a high-pressure environment to atmospheric pressure. This results in instantaneous expansion and partial evaporation of water. The result is a more voluminous and aerated product, especially when it contains high levels of starch.

The final shape and texture depend on factors such as die design, internal temperature and pressure, humidity and residence time, as well as shear forces.

Finally, a rotary cutter cuts the product to the desired size.

4. Drying and cooling

Depending on the type of extrusion, this step varies:

- Wet extrusion (humidity < 18%): requires drying and cooling.

- Dry extrusion (humidity > 18%): cooling only.

The final humidity should be between 2% and 10%depending on their destination (bulk feed, bags or sacks).

Advantages of extrusion in animal feed

Extrusion offers both nutritional and technological manufacturing benefits.

Nutritional benefits

- Increased digestibility

During food expansion, cell walls are broken down, making nutrients more accessible for digestion. This process especially facilitates the release of fats in oilseeds, improving their nutritional utilization and the digestibility of the products.

- Starch gelatinization

Starch gelatinizes during cooking, which increases its digestibility by facilitating enzymatic attack on the amylose and amylopectin chains. Likewise, there are changes in the physicochemical properties of the raw materials, such as density, hygroscopicity and other characteristics.

- Decrease in protein solubility

When proteins decrease their solubilityare less degraded by the rumen flora in ruminants. This is especially important in the feeding of dairy cows.

- Inactivation of anti-nutritional factors

Cooking can inactivate thermolabile anti-nutritional factors such as trypsin inhibitors, gossypol, glucosinolates or aflatoxins. In addition, undesirable enzymes such as lipases and lipoxidases are destroyed, improving food quality and safety.

- Improved palatability

Certain unpleasant odors or tastes are eliminated.

- Sterilization

Harmful organisms such as salmonella are destroyed. Toxins formed by bacterial or fungal activity are also destroyed to acceptable levels.

Technological benefits

- Wide variety of shapes: It is possible to give the finished product the desired shape, such as cylinders, stars, rings or other figures.

- Fair proportion of ingredients: The final product contains all the ingredients of the formula in the right proportion, as in granulation.

- Higher fat content: The formulations allow for a significant increase in fat addition compared to pelleting.

- Longer service life: Thanks to the high temperature of the process, there is a significant decrease in the microbiological level of the final product, which extends its shelf life, provided that it is correctly ensiled.

Disadvantages of extrusion in animal feed

Although it is a very advantageous process, it also has limitations:

- High investment cost in machinery.

- High energy consumption during the operation.

- Maintenance costs significant.

- Partial degradation of vitamins and additives sensitive to heat.

- Risk of overheatingwith loss of nutritional value.

- Requires personnel with specialized technical training.

Extrusion applications in animal feed

Extrusion is currently used to process a wide variety of animal feeds, including fish, crustaceans, pets, dairy cows and raw materials such as cereals and soybeans. Each application takes advantage of the benefits of the process, such as higher digestibility, stability and controlled granule shape.

Food for fish and crustaceans

The feeding of fish and crustaceans has historically been a challenge because of their specific physiological needs and that the power supply represents between 60% and 80% of the total production cost.

Over the last 20 years, feed efficiency has improved significantly: it used to require 2.5 kg of feed to produce 1 kg of fishwhereas now only the following are needed 1.8 kgwhile maintaining the same cost. This is achieved through extruded diets that optimize protein and lipid digestibility, compensating for the limitations of long-chain carbohydrates.

In addition to the nutritional benefits, extrusion allows for customize granule shape and sizeThe range of species that can be fed with compound feeds is widening. Low density pellets or "low sinking pelletsThe "floating cages" sink slowly, giving the fish more time to consume them, reducing feed losses and improving the feed conversion rate. This technique is successfully applied in salmonids and other marine fish in floating cages in Scandinavian countries.

For crustaceans, such as prawns and crayfish, the main challenge is the granule stability in waterwhich must be maintained for 6 to 24 hours. Extrusion makes it possible to achieve this stability using low-cost binders, which makes it the most cost-effective way to achieve this stability. more economical and efficient solution for this type of feed.

Pet food

Pet food consumption has increased significantly in the last decade. Extrusion improves the digestibility of carbohydrates and allows for the control of the shape, texture and hardness of the product.

Feeds can be presented as kibble, bars, rehydratable feeds or special shapes such as stars, adapted to both the animal and the owner's taste. The presentation and visual appeal are key factors, and extrusion offers the flexibility to meet these requirements without compromising nutritional quality.

Feed for high production dairy cows

High-producing dairy cows require supplemental proteins that pass through the rumen without degradationknown as "bypass" protein. Extrusion is ideal for this: the intense heat applied during a short period of time favors the formation of assimilable bypass proteins, preventing them from binding to the detergent acid fiber (D.A.F.) and ensuring an optimal nutritional supply.

Raw material processing

Extrusion is also used to prepare raw materials before incorporation into compound feed, mainly cereals and soybeans.

Extrusion of cereals

Extrusion improves the digestibility of cereals by gelatinizing the starch and destroying the granular structure, which favors nutrient absorption. Extruded cereals are used in feed for piglets, horses, cattle, fish and mink, especially in young animals with still developing enzyme systems. This results in better growth, lower conversion rate and reduction of digestive pathologies..

Soybean extrusion

Extrusion is essential to produce high-energy whole soybeans or Full-Fat Soybeans. By treating soybeans in this way, vegetable oils are incorporated into the particles without risk of oxidation, improving feed digestibility and efficiency.

In addition, extrusion inactivates more than 90% of antitryptic factors, destroys lipases and lipoxidases, and partially eliminates urease, preserving amino acids and increasing nutrient availability. It also protects natural soybean antioxidants, such as phospholipids and tocopherols, preventing oxidation during storage.

The main advantages of extruded soybeans include:

- Increased energy content of feed

- Improved pelleting in high energy feeds

- Improved fat digestion by emulsifying fats

- Balancing of cereal-rich rations due to linoleic acid supply

The future of extrusion in animal nutrition

Extrusion in animal feed has evolved significantly in recent decades, and its future looks even more promising thanks to technological and scientific advances. The following are the main trends and developments that are shaping this technology:

- Artificial Intelligence Integration

The incorporation of intelligent systems in the extrusion lines allows precise control of variables such as temperature, humidity and pressure. Artificial intelligence (AI) facilitates failure prediction, process optimization and feed formula customization according to the specific needs of each species and growth stage.

- High moisture extrusion for moist foods

High moisture extrusion is gaining relevance in the production of wet pet food. This technique improves textureoptimizes the use of ingredients and expands raw material options, allowing the creation of more natural and palatable products for animals.

- Use of alternative raw materials

The industry is oriented towards sustainability through the use of alternative raw materials and agricultural by-products. Extrusion makes it possible to transform these ingredients into high quality feed, reducing waste and environmental impact.

- Microencapsulation for sensitive nutrients

Microencapsulation by extrusion protects heat-sensitive nutrients such as probiotics and omega-3 rich oils. This technology improves the stability and controlled release of these components, ensuring their efficacy in the animal diet.

- Nutritional customization and precision feeding

Extrusion is tailored to offer customized nutritional solutions, optimizing nutrient intake per animal. This allows maximizing growth, health and feed efficiency, aligning with the food trends in livestock farming.