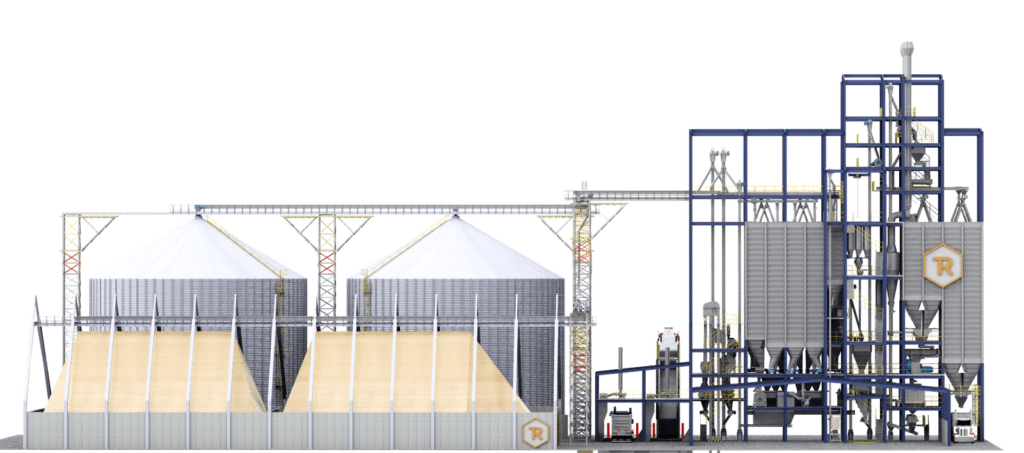

Complete feed mills

We are an international leader with customers on all continents and more than 500 references in the market. The "turnkey" concept refers to the 360º service we offer our customers, from design to commissioning, including construction, assembly, training of plant personnel, consulting and maintenance.

This comprehensive approach ensures that our customers receive a complete and operational solution from day one.

Production phases

In our feed mills we can distinguish the different production phases: product reception, storage, dosing and weighing of raw material, milling, dosing and weighing of correctors, mixing, pelletizing, sieving and storage of the finished product.

Screening

The cleaning of raw materials is an indispensable process in the production chain in order to guarantee the highest level of purity in the final product.

Our screening equipment protects the manufacturing equipment from the presence of wood chips, stones or other particles that may cause damage to the conveying and processing system.

Dosing and weighing

Grinding

With our versatile grinding portfolio, which includes horizontal and vertical hammer mills as well as roller mills, we can cover all your needs. We offer solutions for pre-grinding and regrinding, coarse and fine grinding as well as for the production of granules of different sizes.

Pelletizing

Granulation or pelletizing is the process that converts flour into granules or pellets through the pressure exerted by the rollers against the die of the pelletizing press.

A good pelleting process ensures that the feed is more easily digestible by the animals and, in addition, of higher quality and durability.

Extrusion

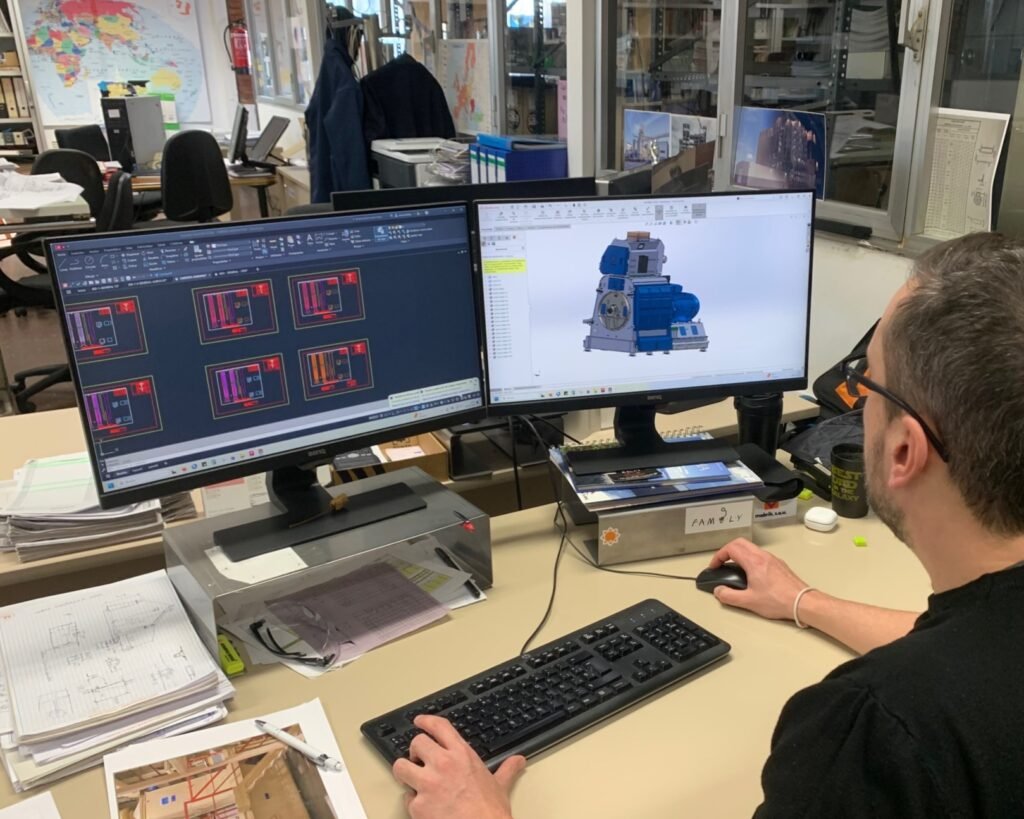

Design and engineering services

What kind of services are offered?

- Development of new plants

- Upgrading of existing installations

- Civil works

- Design and distribution of process equipment

- Metal buildings

- Electrical coordination services

- Automation coordination services

What design tools are used?

- SolidWorks

- Autodesk AutoCad

- ScketchUp

- CYPE

- Tekla

- 3D laser scanner

In-house manufacturing

In our production plants, located in Santa Perpetua de Mogoda, near Barcelona, we manufacture all our machinery using quality materials and components of leading brands. We have workshops equipped to carry out machining, cutting, bending and welding processes. We internally manage the design, manufacture and assembly of each piece of equipment. Our facilities allow us to adapt to the specific needs of each project.

Assembly and installation services