SCREENING

Flour sifter

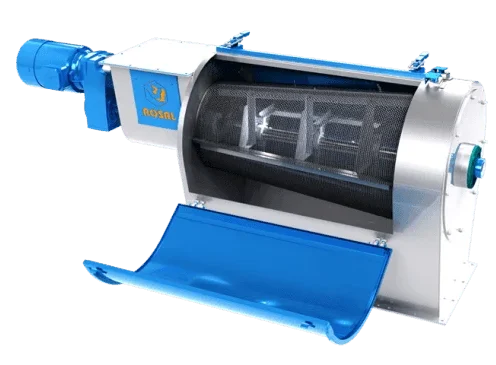

Designed for high hygiene and maximum food safety, the flour sifter, also known as flour sifter, is a key component in the production line.

Its function is to filter and separate foreign agents such as iron, stones or cardboard from the flours to ensure the highest level of purity in the final product.

Features

Design

Self-cleaning rotary screen with fast access

The flour sifter operates with a rotating drum equipped with a screen of variable diameters. A rotor with arms and nylon brushes continuously clean the sieve to prevent blockages and maintain product flow. It incorporates hinged side gates and safety latches for quick access for cleaning and inspection.

Models

| Model | Motor power (kW) | Grill diameter (mm) | Maximum capacity (Tn/h) |

|---|---|---|---|

| CH-531 | 5,5 | 12 | 25 - 30 |

| CH-541 | 7,5 | 12 | 50 - 60 |

| CH-551 | 15 | 14 | 100 |

| CH-561 | 18,5 | 14 | 150 |

| CH-571 | 18,5 | 14 | 200 |

Frequently Asked Questions

They can be installed at the flour inlet to eliminate by-products and minerals, or after the mixer, before the pelletizer, in order to protect the latter from any foreign body that could be incorporated into the flour during the process.

Our flour sifters are specially designed to meet the needs of the agro-industrial sector:

Compound feed mills

Cereal processing plants

Flour mills

Pet food factories

Biomass plants

Extrusion plants

Oilseed handling

Handling of cereals, flours and their by-products in general

Staggered maintenance is recommended:

Weekly: dust cleaning and visual control.

Monthly: revision of sieves, brushes and electrical connections.

Annual: thorough cleaning of the interior and greasing of shafts.

Every 10 years: disassembly of the motor, replacement of bearings and seals.

It is certified for areas classified as ATEX Zone 22 (explosive dust environments), complying with Directive 2014/34 EU, which guarantees its safe use in environments with risk of explosion.

They should not be used with products that do not flow easily or that have a high dust explosive index, as these could create unsafe conditions during screening.

It has 2 outlets, one for clean product and one for impurities or unwanted materials, facilitating efficient in-line separation.

Request more information

Leave us your data and questions and a flour sifter technician will advise you without obligation. Let's talk!

Related machinery

Grain cleaner

Pre-cleaners are designed to protect manufacturing equipment from wood chips, stones and other particles.

Rotary screen

Rotary screens are used to separate fines from pellets in different sizes and capacities.