CONVEYING

Chain conveyor

The chain conveyor performs a basic function in a feed mill, carrying out the transport of cereals, flours, pellets, flakes and extrudates at any stage of the production line. Chain conveyors are ideal for covering long lengths and for the extraction of the product from underneath the hoppers.

Manufactured in carbon steel with galvanized finish or in AISI 304 stainless steel for humid environments, these conveyors offer high resistance and durability. Rosal offers a wide range of conveyors with capacities from 35 to more than 650 m³/h.

Features

Motor

Direct drive with elastic coupling

Our chain conveyors are equipped with an elastic coupling system in the drive. This system acts as a buffer against overloads or jams, protecting the conveyor from damage and preventing unexpected stops. In addition, its ability to smooth operation improves operating efficiency, ensuring continuous, uninterrupted production.

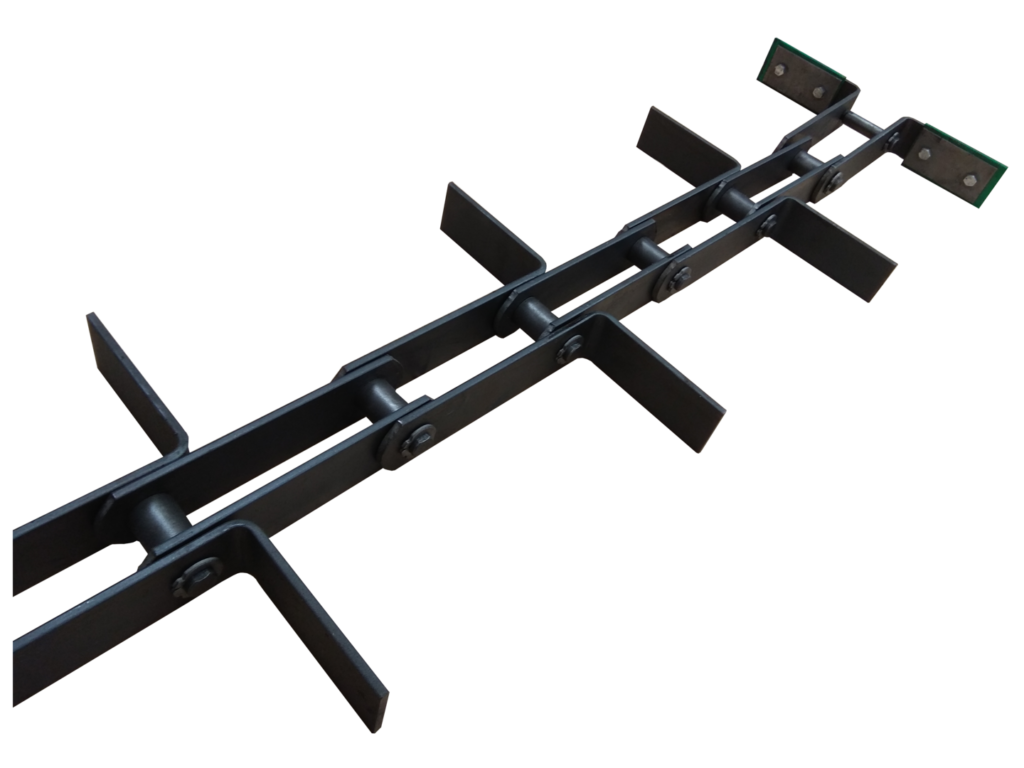

Chain

Heat-treated or forged link chain

The chain is composed of high-strength links and undergoes heat treatment to significantly enhance its properties. This process increases hardness and wear resistance, resulting in greater durability and reliability even under demanding operating conditions.

Models

| Model | Total section | Capacity (m3/hour) |

|---|---|---|

| TC-1 | 175x250 | 35 - 53 |

| TC-2 | 200x290 | 49 - 74 |

| TC-3 | 260x360 | 87 - 131 |

| TC-4 | 320x470 | 141 - 211 |

| TC-5 | 400x540 | 201 - 301 |

| TC-6 | 500x650 | 316 - 474 |

| TC-7 | 600x650 | 380 - 571 |

| TC-8 | 700x650 | 445 - 668 |

Frequently Asked Questions

A chain conveyor moves material by means of a chain that pulls the product along a closed trough. The chain is driven by a motor and travels on internal guides, pushing the material from the loading point to the discharge point continuously.

Chain conveyors are typically installed in horizontal conveying lines for raw or intermediate materials like cereals, flours, or granules. They are commonly placed between storage silos, dosing scales, mills, mixers, or truck loading systems.

Our chain conveyors are specially designed to meet the needs of the agro-industrial sector:

Compound feed mills

Cereal processing plants

Flour mills

Pet food factories

Biomass plants

Extrusion plants

Oilseed handling

Handling of cereals, flours and their by-products in general

The conveyor requires periodic maintenance at different levels, ranging from weekly cleaning to thorough overhauls every few years. Maintenance tasks include dust removal, checking and adjusting chain tension, lubricating bearings, and inspecting the electrical system. Adhering to these schedules ensures safe and efficient long-term operation.

All of our chain conveyors are certified ATEX EX II 3D T 195°C. This certification ensures the equipment is safe for use in environments with occasional combustible dust presence (zone 22). It confirms that the equipment is designed to prevent any risk of ignition, even under demanding conditions, meeting the highest industrial safety standards.

There are extractor models, designed to be placed under hoppers or silos to extract bulk materials, and conveyor models for continuous horizontal movement. In addition, they can be single or double-deckers to suit different unloading needs.

Request more information

Leave us your data and questions and a chain conveyor technician will advise you without obligation. Let's talk!

Related machinery

Bucket elevator

Bucket elevators are machines for vertical product conveying.

Flight conveyor

The paddle conveyor is designed to ensure proper pellet handling.

Screw conveyor

Screw conveyors are equipment designed to transport products horizontally or vertically.