CONVEYING

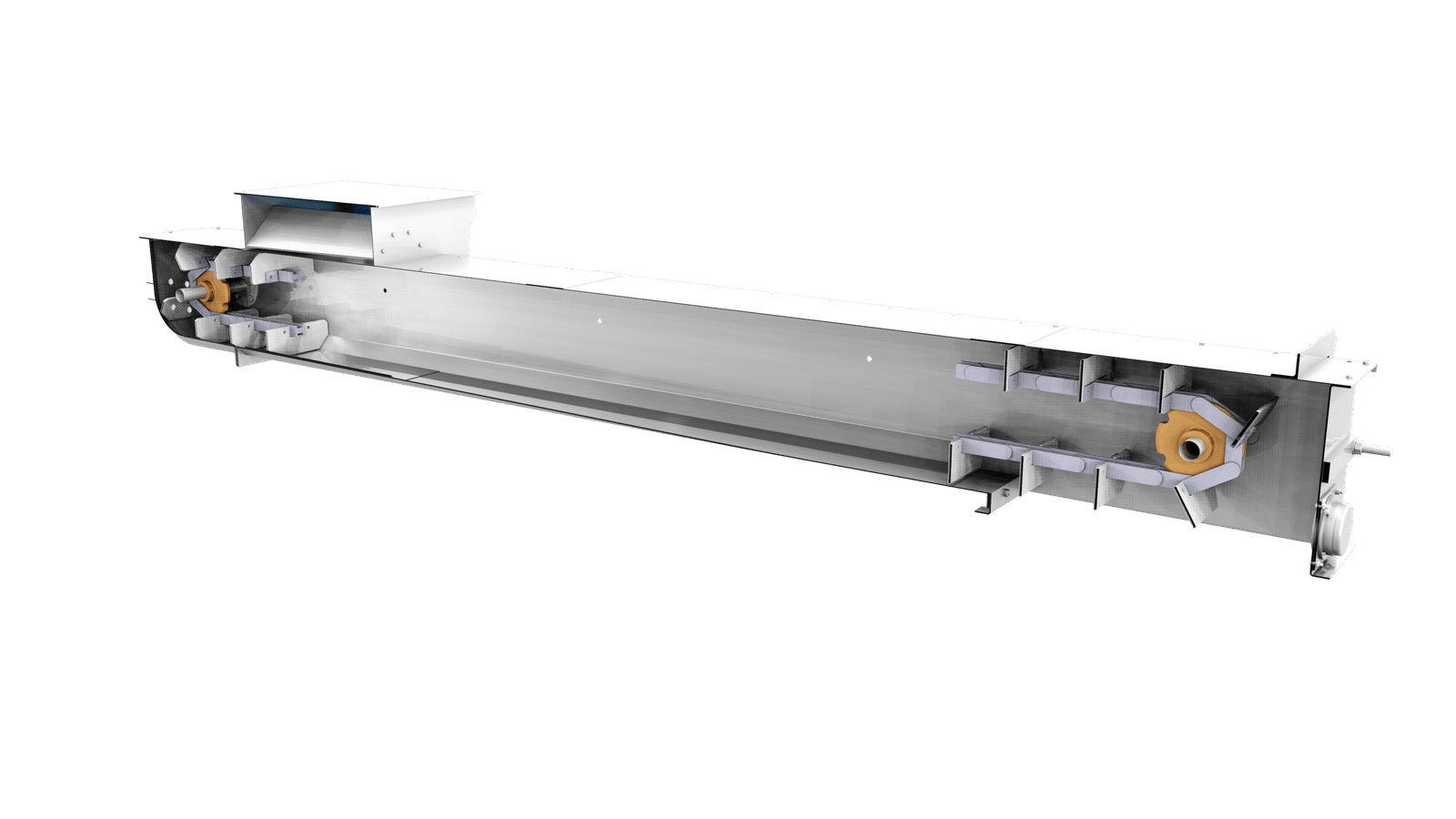

Flight conveyor

The flight conveyor is a chain conveyor system fitted with hardened plastic paddles, designed to ensure smooth and efficient pellet handling.

Pellets require the most careful and gentle handling possible to minimize the generation of excess fines. Whenever possible, they should be moved by gravity at low heights. When gravity handling is not feasible, conveying systems that ensure a non-aggressive treatment of the pellets should be used.

Features

Installation

Installation flexibility

Paddle conveyors are installed underneath the pelletizers to receive the newly formed pellets in a gentle and efficient manner. Thanks to their design, these conveyors can be configured with an inclination of up to ten degrees, which facilitates material flow without compromising pellet integrity or generating excess fines.

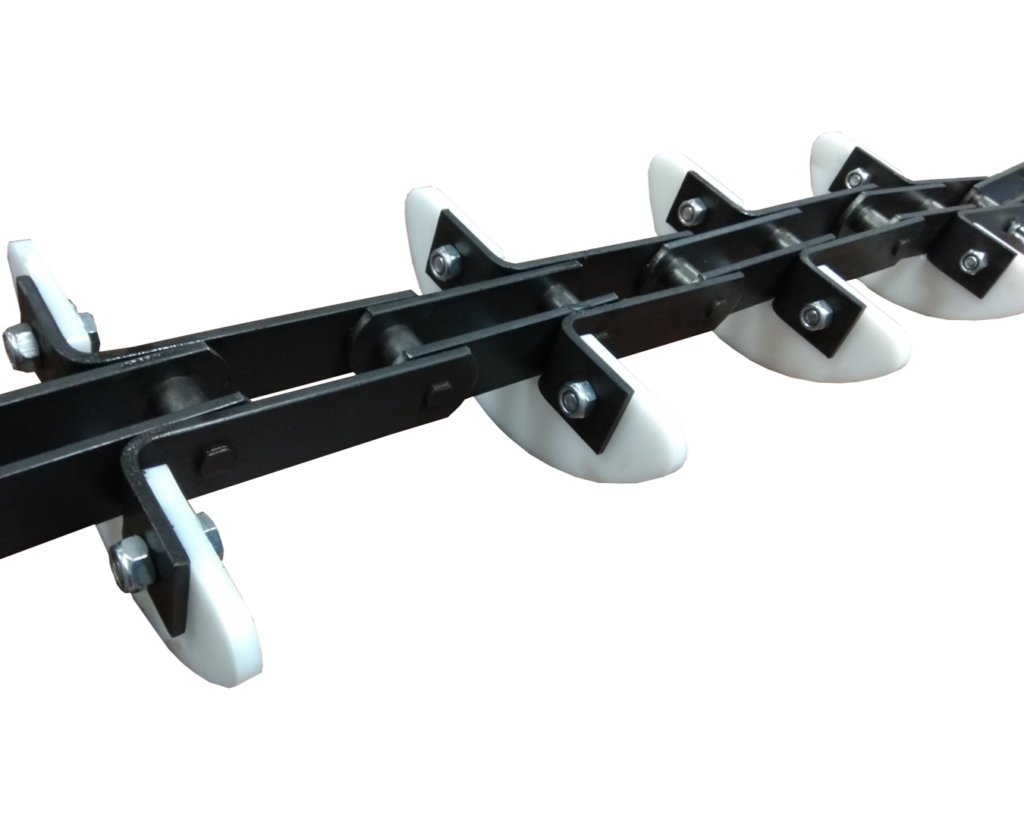

Chain

Treated steel chain with bolted high-strength blades

The treated steel chain with bolt-on heavy-duty pellet blades is engineered for both durability and ease of maintenance. The bolt-on paddles allow for quick and straightforward replacement, minimizing downtime in case of wear or damage.

Models

| Model | Total section | Capacity (m3/hour) |

|---|---|---|

| TG-175 | 175 | 30 |

| TG-250 | 250 | 60 |

| TG-300 | 300 | 100 |

Frequently Asked Questions

A flight conveyor is an industrial machine designed to transport product smoothly and in a controlled manner from the inlet to the discharge point. The movement is achieved through plastic paddles attached to a chain, which push the material along the channel without causing damage or compaction.

They are typically installed at the end of the pelletizing line, directly beneath the pellet crumbler, where they collect the product for discharge into the bucket elevators.

Our flight conveyors are specially designed to meet the needs of the animal feed sector:

Compound feed mills

Cereal processing plants

Flour mills

Pet food factories

Biomass plants

Extrusion plants

Oilseed handling

Handling of cereals, flours and their by-products in general

The conveyor requires periodic maintenance at different levels, ranging from weekly cleaning to thorough overhauls every few years. Maintenance tasks include dust removal, checking and adjusting chain tension, lubricating bearings, and inspecting the electrical system. Adhering to these schedules ensures safe and efficient long-term operation.

All of our pallet conveyors are certified for ATEX EX II 3D T 195°C. This certification ensures the equipment is safe for use in environments with occasional combustible dust presence (zone 22). It confirms that the equipment is designed to prevent any risk of ignition, even under demanding conditions, meeting the highest industrial safety standards.

Both conveyors use a chain as the dragging mechanism but differ in design and application. The chain conveyor moves the material directly with metal links, making it more robust and suitable for dense or abrasive products. In contrast, the paddle conveyor features plastic paddles bolted to the chain, enabling gentler transport that is ideal for pellets and other delicate materials.

Request more information

Got questions? Leave your details and a flight conveyor expert will contact you — no strings attached. Let’s talk!

Related machinery

Bucket elevator

Bucket elevators are machines for vertical product conveying.

Chain conveyor

The chain conveyor is ideal for covering long lengths and for the extraction of product from under hoppers.

Screw conveyor

Screw conveyors are equipment designed to transport products horizontally or vertically.