CONVEYING

Screw conveyors

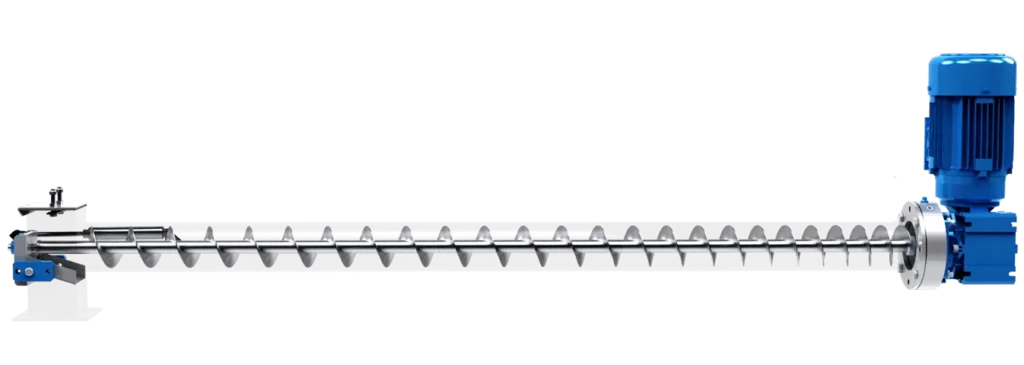

Screw conveyors are equipment for conveying product horizontally or vertically by means of a worm screw that rotates carrying the product forward. This conveying system is mainly used to transport granular materials, cereals, minerals and flours in the agricultural, industrial, mining, chemical, environmental, etc. sectors.

Features

Models

Wide range of models

Models

| Diameter | Step | Capacity (m3/hour) |

|---|---|---|

| 150 | 150 | 11 |

| 180 | 180 | 19 |

| 200 | 200 | 28 |

| 250 | 250 | 55 |

| 300 | 300 | 79 |

| 350 | 350 | 126 |

| 400 | 400 | 188 |

| 450 | 450 | 207 |

| 500 | 500 | 130 |

Frequently Asked Questions

A screw conveyor works by means of a helical screw that rotates inside a tube, moving the product along the shaft. It is ideal for moving bulk products in a continuous, efficient and controlled manner.

This type of machinery is designed for products with good flow behavior, such as:

Cereals (corn, wheat, barley, etc.)

Flours and milling by-products

Granules and powders

They are generally located in the dosing line, between the additive silos and the hopper or weighing scale. Their function is to accurately dose and transport the micro-ingredients to the mixing system.

Our screw conveyors are specially designed to meet the needs of the agro-industrial sector:

Compound feed mills

Cereal processing plants

Flour mills

Pet food factories

Biomass plants

Extrusion plants

Oilseed handling

Handling of cereals, flours and their by-products in general

Maintenance will depend on use and working conditions, but in general it is suggested:

Every 50 h: dust cleaning and greasing of bearings (if applicable).

Every 500 h: check chain, electrical connections and possible leaks.

Every 2,000 h: inspect bearings and stuffing boxes.

Every 25,000 h: check gearboxes and replace bearings if necessary.

It is recommended to adjust these intervals according to the environment and always follow the manufacturer's instructions.

Our screw conveyors comply with Directive 94/9/EC (ATEX 95a) and are certified to operate exclusively in ATEX zones classified as Zone 22, i.e. areas where a dust explosive atmosphere is only expected under abnormal conditions and for short periods.

Request more information

Leave us your data and questions and a screw conveyor technician will advise you without obligation. Let's talk!

Related machinery

Bucket elevator

Bucket elevators are machines for vertical product conveying.

Flight conveyor

The paddle conveyor is designed to ensure proper pellet handling.

Chain conveyor

The chain conveyor is ideal for covering long lengths and for the extraction of the product from underneath the hoppers.