EXTRUSION

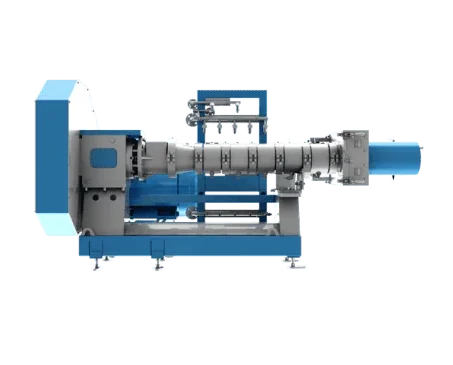

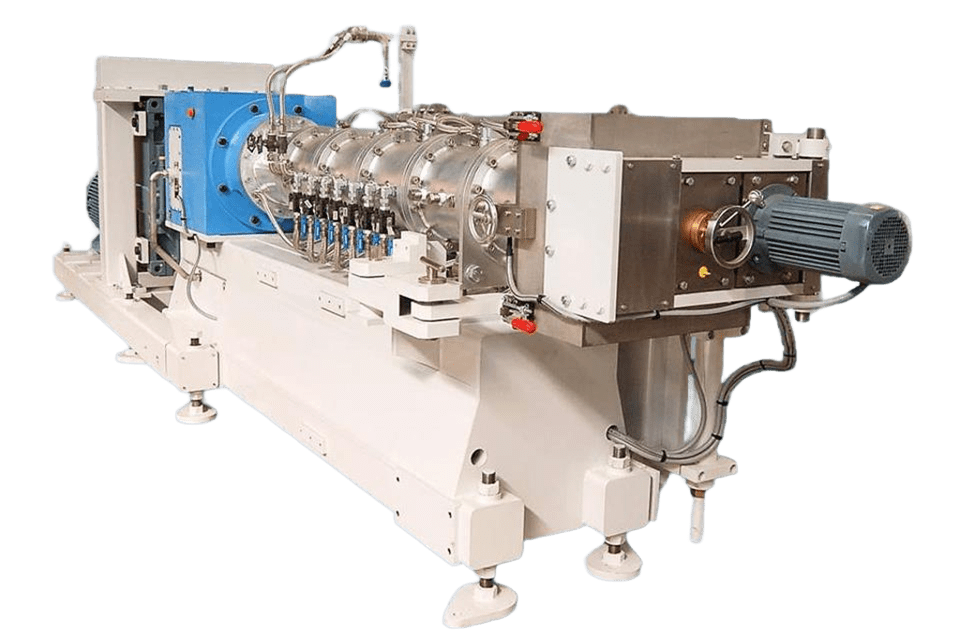

Single screw extruder

Features

Design

Drive and extrusion booth

The single screw extruder is driven by an electric motor with direct drive or by pulleys and V-belts adjusted with a tensioning system. The extrusion cabin is adaptable, with different chambers or barrels according to the required capacity, and has double-wrapped chambers that allow the passage of steam or water for precise temperature regulation.

Versatility

Adjustable cutting system

The cutting section includes adjustable knives on an articulated support, driven by a variable speed motor. This allows changing the length of the extruded product without stopping the machine. In addition, it has an interchangeable nozzle that defines the final profile and affects the internal pressure and the quality of the cut and expansion.

Frequently Asked Questions

Extrusion significantly improves the digestibility of ingredients (especially starches), eliminates anti-nutritional factors (such as trypsin inhibitors in soybeans) and sterilizes the product by heat and pressure, eliminating germs such as salmonella. It also makes it possible to modify texture, expand the product and optimize palatability.

The Rosal extruder can process a wide variety of raw materials for animal feed, such as whole soybeans, cereals (corn, wheat, barley), oilseed by-products and formulated blends. Thanks to its modular design, it is ideal for producing extruded feeds, balanced feed, precooked meals and products with high digestibility and nutritional value.

During the extrusion process, the machine can reach temperatures up to 170 °C and pressures close to 30 bar, depending on the type of product and screw configuration. This high pressure and heat environment favors rapid cooking, starch gelatinization and final product expansion.

The modular system includes single-threaded, double-threaded, long and tapered screws, which can be combined to adjust compression, friction and product feed. Airlocks control internal pressure and increase shear temperature. This flexibility allows the machine to be adapted to different formulas and working conditions.

The Rosal extruder incorporates double-wrap chambers in the barrels, which allow the passage of water or steam for precise temperature control in each section of the process. In addition, manual valves, manifolds and PT100 temperature probes are included for efficient and safe thermal management.

Yes, the Rosal extruder has a motorized cutting system with real-time adjustable blades. The operator can adjust the length of the extruded product during operation by varying the speed of the cutting motor or the distance between blades and nozzle, which improves production flexibility.

Preventive maintenance includes draining oil from the bearing housing every 2,000 hours, monthly greasing of the blade system, and regular inspection of screws, chambers and airlocks for wear. Low flow or unusual temperature are signs that modular elements need to be replaced.

To avoid the phenomenon of "blow-out" or pressure build-up in specific areas, it is key to ensure continuous feeding, a balanced assembly of screws and airlocks, and to maintain the proper moisture content in the mixture. It is also important to perform preventive cleaning of the sleeve to remove accumulated residues.

The start-up time may vary depending on whether steam is used or not. Generally, thermal and pressure equilibrium is reached in 5 to 10 minutes. During this time, the product flow is regulated, the humidity is stabilized and the cut is adjusted until the desired texture and cooking of the extrudate is obtained.

The extruder supports interchangeable flat or conical nozzles, with multiple orifice configurations (shapes: star, fish, flower, heart, etc.). These nozzles determine the shape, size and degree of expansion of the final product and allow customizing the design according to the target market (fish, birds, pets, etc.).

Request more information

Leave us your data and questions and an extrusion technician will advise you without obligation. Let's talk!

Related machinery

Pellet conditioner

Conditioners generate the heat treatment necessary to prepare the product prior to pelletizing.

Pellet mill

Mabrik industrial pellet mills are built with high quality materials and great robustness.

Hammer mill

Our hammer mills guarantee efficient and uniform grain grinding.

Ribbon and paddle mixer

Ribbon or paddle mixers ensure effective homogenization.