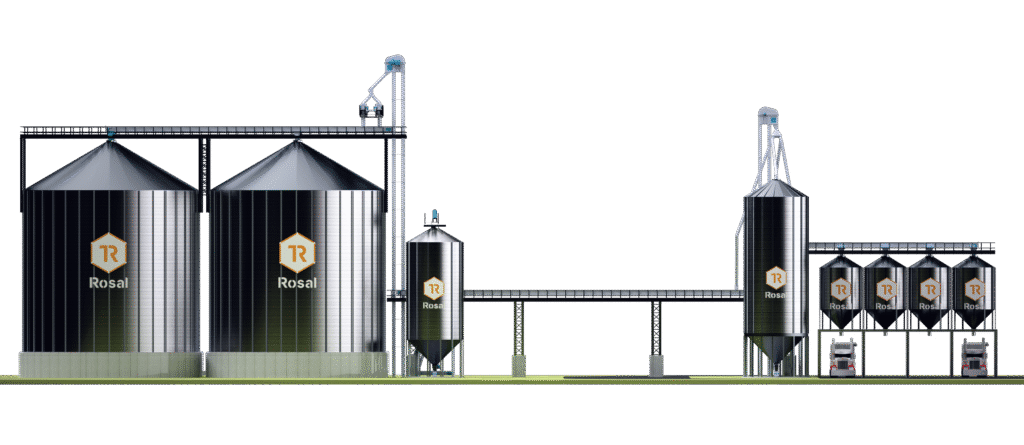

STORAGE

Grain silos

Features

Capacity

Square silos

Square silos offer up to 25% more storage capacity than round silos with the same surface area, making them ideal for bulk goods.

The body of our silos is built in "ZIG-ZAG" folded sheet metal at a 60º inclination, with hoppers and counter hoppers designed to ensure the correct inclination according to the product. They incorporate inspection and maintenance gates and suction filters in the upper part.

Conservation

Cylindrical silos

Cylindrical silos, with sloping roof and flat bottom or hoppers with adjustable slope, are suitable for storing grains, cereals, seeds and flours. They are ideal for the storage of large volumes of raw materials for extended periods of time, available in various capacities, heights and diameters.

Frequently Asked Questions

Flat bottom silos allow for greater storage capacity and are ideal for extended storage. Their design facilitates better grain management with efficient sweeping and ventilation systems.

Thanks to their Z-600 quality zinc coating (600 g/m²), these silos are highly resistant to corrosion, with a long service life even in aggressive or humid environments.

They are designed according to ANSI ASAE EP 433. This guarantees a safe design and conforms to international agronomic standards.

Yes, these silos incorporate anti-seismic reinforcements designed to resist seismic accelerations of up to 0.2 g, in accordance with UBC standards.

They include multiple access points: interior door, eave platform, vertical stairs from the ground, walkways and automatic locking system for operator safety.

They are equipped with an aeration system composed of fans and aeration domes that keep the grain in optimal conditions for long periods of time.

By means of mechanical sweeping with a central tractor, which allows an efficient and complete discharge of the contents, even in products with low fluidity.

They are designed to withstand wind speeds up to 144 km/h, equivalent to 100 kg/m² or 0.98 kN/m² lateral load.

Includes complete roof, galvanized hardware quality 8.8 or 10.9, anchor kit, level sensors, aeration system, platforms, ladders and safety access.

Request more information

Leave us your data and questions and a grain silo technician will advise you without obligation. Let's talk!

Related machinery

Steel structures

Metal structures designed to support the weight of the entire storage system of a feed mill.