When we think of animal feed, we usually think of bulky ingredients such as cereals, protein meals or oils. However, much of the production performance and nutritional balance depends on substances that are added in minute quantities: vitamins, trace minerals, synthetic amino acids or enzymes. The big challenge is that these ingredients, although essential, are used in such small proportions that it would be impossible to distribute them evenly if they were added directly to the mixer.

This is where premixes come into play: concentrated preparations designed to facilitate the precise and homogeneous incorporation of micronutrients. Their use is so widespread that today there is practically no modern factory that does not rely on them. Several authors, such as Cromwell (1995) or Baker (1995), have highlighted their role in the transition from simple formulation systems to precision nutrition models.

What is a premix

A premix is a carefully formulated combination of micronutrients - from vitamins and trace minerals to enzymes or synthetic amino acids - incorporated into a carrier to ensure homogeneous mixing.

The key feature is that it contains ingredients at very low inclusion levels, but evenly distributed thanks to the carrier and pre-mixing process.

This design responds to a basic principle: if an ingredient must be incorporated in micrograms or milligrams per kilogram of feed, its direct dosing would generate irregularities, losses, compaction or simply unavoidable human error. Premixing ensures that each batch of feed contains exactly what is intended in the formulation.

The technological value of premixing within the plant

The use of premixes is not only of nutritional interest, but also of technological and operational importance. A plant that handles dozens of micronutrients separately is exposed to mismatches, delays and significant deviations between batches. When these same ingredients arrive grouped together in a stable mix, the process becomes smoother and more traceable.

In addition, many micronutrients present stability or handling challenges. Some vitamins are sensitive to light or temperature; certain minerals tend to compact; and liquid amino acids require specific storage conditions. The premix acts as a “protective vehicle,” allowing these components to reach the final product in optimal condition. Studies such as those by Henry (1995) and Ammerman et al. (1995) have pointed out that stability is a crucial part of the value of a premix.

Composition: what they contain and why

Although the exact content depends on the animal species and the production objective, premixes usually include:

- Group B, A, D and E vitamins.

- Trace minerals such as Zn, Cu, Mn, Fe, Co, and Se.

- Industrial amino acids (lysine, methionine, threonine, tryptophan).

- Enzymes designed to improve digestibility (phytases, xylanases, proteases).

- Technological substances such as antioxidants or anti-caking agents.

The choice of each ingredient is influenced both by physiological needs and by the bioavailability of its sources. For example, numerous studies have shown that variability in the quality of phosphorus and calcium among raw materials can be very high (Hall, 1997; CVB, 1997). Without a premix that harmonizes dosage, such variation would have a direct impact on animal performance.

| Component | Main function | Practical commentary |

|---|---|---|

| Vitamins | They regulate metabolic and physiological processes. | Some require protection against light, heat or minerals. |

| Trace minerals | Bone formation, enzymes, immunity | Their bioavailability varies according to the source |

| Industrial amino acids | Adjust the protein profile without excess of crude protein | Avoid energy losses and reduce nitrogen excretion |

| Enzymes | Improved digestibility and better utilization of raw materials | Phytase, xylanases and proteases are the most commonly used. |

| Antioxidants | Protect vitamins and fats from oxidation | Indispensable in diets rich in lipids |

| Acidifiers | Stabilize pH and improve intestinal health | Very useful in early stages |

| Technological additives | Improve flow, texture and stability | Anti-caking agents, sequestering agents, flavoring agents |

The manufacturing process: how to achieve a truly homogeneous blend

The premix production involves a chain of steps designed to ensure homogeneity and stability:

- Selection and analytical verification of each micronutrient.

Purity, origin and particle size are controlled. Small differences can alter the final blend. - Accurate dosage of ingredients.

The incorporation of micronutrients is not done manually, but by means of dosing equipment such as highly sensitive electronic scales, screw conveyors or small calibrated tanks. This equipment allows the incorporation of quantities ranging from grams to a few kilograms, minimizing human error and ensuring that each ingredient enters the mixture in the exact amount foreseen by the formulation. - Incorporation of a support or carrier.

Calcium carbonate, inert flours or ingredients of stable fluidity are usually used. This support allows micronutrients to be properly distributed. - Intensive mixing.

Specialized manufacturers work with mixers which reach very low coefficients of variation (less than 5%). In a standard feed mill, where much larger volumes and raw materials with very different particle sizes (cereals, flours, fats...) are handled, it is very difficult to maintain such uniformity. The very physical behavior of the ingredients and the scale of the mixer make achieving such low CVs practically impossible without a premix line.

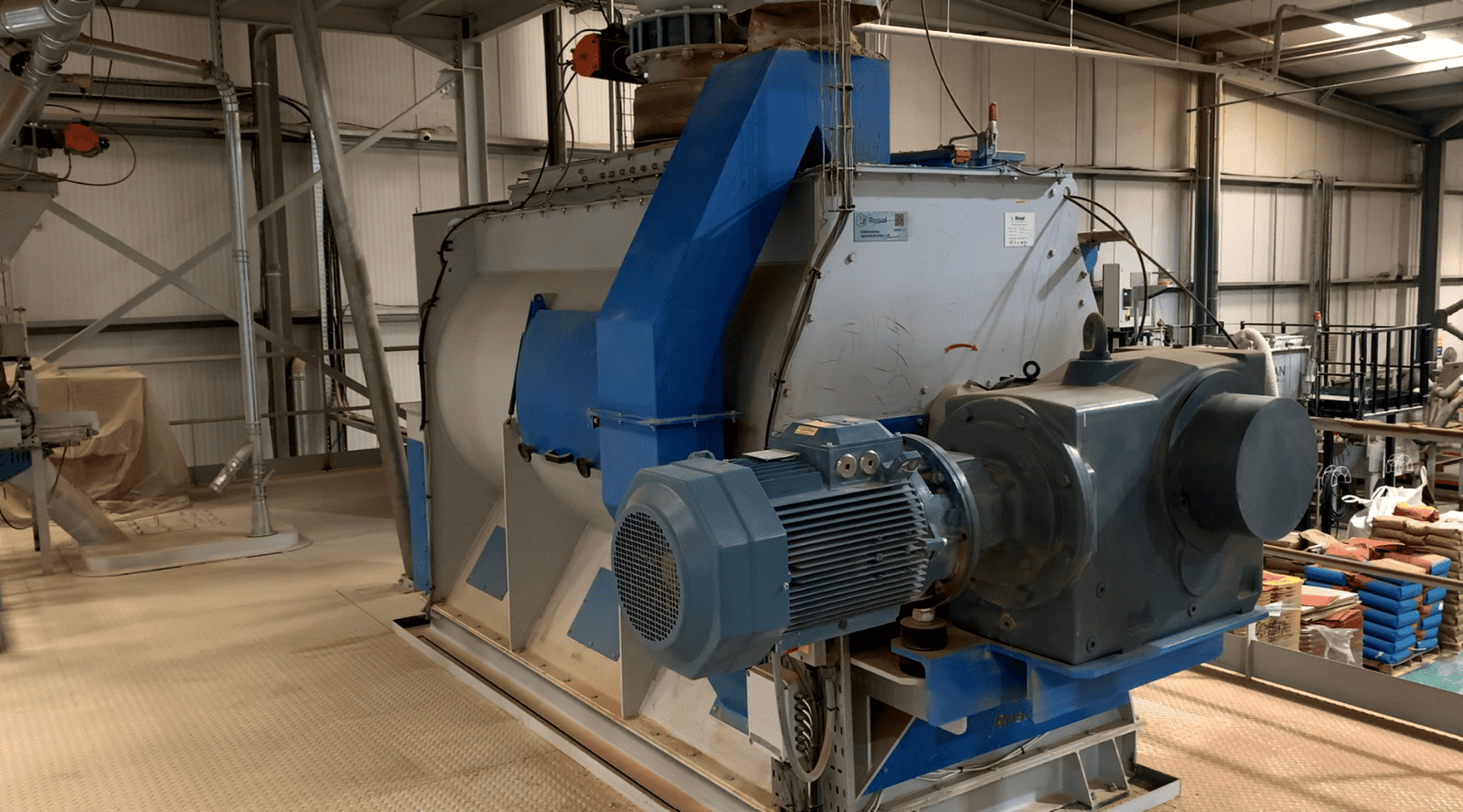

Premix mixer at a premix plant in Stamford, England, developed by Rosal-Mabrik. - Subsequent quality control.

This includes analysis of uniformity, solubility, fluidity and evaluation of possible interactions between ingredients.

Studies cited in the paper, such as those by Roland and Bryant (1994) or Martin and Gai (1995), explain that even small mismatches in these steps can alter the availability of calcium, phosphorus or vitamins.

Key differences between producing feed and producing premixes

Although both processes are part of the animal feed industry, manufacturing feed and producing premixes involve very different logic, machinery and objectives.

In a traditional feed mill, the focus is on moving large volumes: receiving raw materials, grinding, mixing, pelleting and loading. Mixing is carried out in high-capacity equipment with highly heterogeneous ingredients, which makes it difficult to maintain perfect homogeneity—especially when micronutrients are added in very small quantities. In addition, the inherent variability of agricultural raw materials requires continuous adjustments between batches.

Premix plants, on the other hand, work with concentrated, high-value ingredients where the priority is not volume but precision. They use micro-dosers, highly sensitive scales and high-energy mixers designed to achieve very low coefficients of variation. Here, every gram matters: even a minimal deviation in a mineral or vitamin can be magnified when the premix is incorporated into the final feed. For this reason, these plants typically have in-house laboratories and stricter quality controls than a conventional feed mill.

Economically, feed manufacturing operates with narrow margins and economies of scale—producing many tons per hour is essential for profitability. Premix companies, however, work with lower volumes but higher added value, basing their competitiveness on technical quality, formulation and product stability rather than mass production.

In short, the feed mill seeks industrial efficiency, while the premix plant guarantees nutritional accuracy. The two systems are complementary: feed provides energy and structure; the premix provides precision and safety.

| Appearance | Traditional feed mill | Premix plant |

|---|---|---|

| Main objective | Produce large volumes of complete feed | Ensuring accuracy and homogeneity in micronutrients |

| Production volume | Very high (tons/hour) | Medium or low |

| Key equipment | Grinding mills, high capacity mixers, pelletizers | Microdosers, precision scales, high energy blenders |

| Process variability | High due to the heterogeneity of raw materials | Low, highly controlled processes |

| Homogeneity control | Moderate, depending on mixer and materials | Very strict (low CV, constant analytical control) |

| Cost/margin | Narrow margins, economies of scale | Higher value-added margin |

| Main risks | Micro-ingredient dosing errors, batch to batch variation | Particle segregation, interaction between vitamins and minerals |

| Need for laboratory | Less intense | Fundamental to guarantee purity and stability |

| Differentiated value | Fast and efficient production | Accurate and safe nutrition |

Benefits: why premixes are considered indispensable

One of the most widely recognized points in the literature is that premixes provide nutritional security. By minimizing batch-to-batch variability, they reduce the risk of subclinical deficiencies, intoxications or irregular performance.

They also greatly simplify internal logistics. Instead of handling 20 different ingredients, the operator adds one or two ready-made bags. This reduces the margin of error and speeds up the production process. Cromwell (1995) highlights this point when describing how the industrialization of feed manufacturing has significantly improved production control.

Another benefit is micronutrient stability. Some compounds are sensitive to oxidation or degrade when exposed to moisture or heat. In a premix, they are often combined with antioxidants or stabilizers that extend their shelf life.

| Advantage | Summary explanation |

|---|---|

| Feed uniformity | Ensures that micronutrients are evenly distributed even in large batches. |

| Error reduction | Avoids manual dosing errors of low inclusion ingredients. |

| Improved handling and fluidity | The premix support facilitates mixing and avoids caking. |

| Greater stability of micronutrients | Helps protect sensitive vitamins and reactive minerals. |

| Traceability and control | Simplifies audits, records and quality analysis. |

| Process optimization | Reduces time, reprocessing and returns due to defective batches. |

| Increased animal performance | Minimizes nutritional variability and avoids subclinical deficiencies. |

How to evaluate the quality of a premix

The quality of a premix depends not only on its composition, but also on deeper factors:

- Purity and origin of each raw material. Publications such as those of CVB (1997) show the important variability between mineral sources.

- Particle size. Irregular particle sizes cause segregation during transport.

- Physical behavior of the support. A carrier inadequate can absorb humidity or generate caking.

- Compatibility between ingredients. Some vitamins and minerals should not come into direct contact without prior protection.

- Manufacturer's warranties. Batches must be accompanied by analytical certificates and clear specifications.

The nutritionist or technician should consider all these elements when choosing a suitable premix.

Limitations and frequent errors

Although premixes are extremely reliable tools, their misuse can cause problems. A common mistake is assuming that all premixes are equivalent, when in fact they differ greatly in composition, stability and bioavailability.

They should also not be added too late in the process, as some ingredients require specific mixing times to integrate properly.

Another common mistake is believing that a premix automatically compensates for the poor quality of other raw materials. Precision nutrition requires consistency across all feed ingredients.

Conclusion

Premixes are an efficient solution for incorporating micronutrients homogeneously, stably and safely into animal feed. Their use has enabled levels of control and precision that were unthinkable just a few decades ago. Works such as those by Ammerman et al. (1995), Baker (1995), Hall (1997) and Cromwell (1995) show that the consolidation of premixes has been key to the professionalization of modern animal nutrition.

Understanding what they are, how they are manufactured and which factors determine their quality allows nutritionists, farmers and technicians to get the most out of feed and ensure that each animal receives a balanced diet tailored to its needs.

References

- Ammerman, C.B., Baker, D.H., & Lewis, A.J. (1995). Bioavailability of nutrients for animals: Amino acids, minerals, vitamins, etc.. Academic Press.

- Baker, D.H. (1995). Nutrient bioavailability: Digestibility and metabolism. In: Ammerman, C.B., Baker, D.H., & Lewis, A.J. (eds.). Bioavailability of nutrients for animals. Academic Press.

- Cromwell, G.L. (1995). Feeding and efficiency in swine nutrition. In: Ammerman, C.B., Baker, D.H., & Lewis, A.J. (eds.). Bioavailability of nutrients for animals. Academic Press.

- CVB (1997). Feed Table. Centraal Veevoeder Bureau (The Netherlands).

- Hall, J.W. (1997). Variability in phosphorus and calcium sources for animal feed. In: Proc. Carolina Nutrition Conference.

- Henry, Y. (1995). Stability and interactions of vitamins and trace elements in premixes. In: Ammerman, C.B., Baker, D.H., & Lewis, A.J. (eds.). Bioavailability of nutrients for animals. Academic Press.

- Martín, L., & Gai, F. (1995). Homogeneity in feed mixtures and stability of microingredients. Journal of Animal Nutrition.

- Roland, D.A., & Bryant, M. (1994). Calcium sources and solubility in feed manufacturing. Poultry Science.