Definition and operation of screens

What is a sieve?

A screen is a device used to separate materials of different sizes. Basically, consists of a perforated or mesh surface that allows smaller particles to pass through while retaining larger particles. Screens can be made of various materials such as steel, polymers or even natural materials, depending on the specific application and the characteristics of the material to be processed.

How does a sieve work?

The principle of operation of a screen is relatively simple but highly effective. The material that needs to be classified is placed on the surface of the screen. Through vibratory or rotary movements or simply by gravity, the smaller particles pass through the perforations or meshes, while the larger ones remain on the surface. This screening process ensures that only particles of the desired size are filtered outThis facilitates further processing of the material.

Types of screens

Fixed screens

Fixed screens are those that do not have their own movement. They are used in processes where the material flows continuously over the screen surface. This type of screen is common in industries where the volume of material to be processed is high and extreme accuracy in particle separation is not required.

Vibrating screens

Vibrating screens are much more versatile and effective for materials that require more precise separation. These screens use mechanical vibration to improve screening efficiency.. They are especially useful in industries such as mining, construction and animal feed, where accuracy and speed in sorting are crucial.

Rotary screens

Rotary screens, also known as trommels, are perforated cylinders that rotate on their axis. This rotary motion allows for efficient and continuous separation of materials. They are widely used in the recycling industry, agriculture and in mineral processing plants, due to their ability to handle large volumes of material on a consistent basis.

Screen applications

Mining industry

In the mining industry, screens are essential for the separation of minerals and rocks of different sizes. They allow a more efficient processing of the extracted materials, improving the quality of the final product and reducing operating costs. Vibrating and rotary screens are particularly common in this sector.

Agricultural industry

In the agricultural sector, sieves are used to clean and classify grains and seeds. By removing impurities and separating grains by size, product quality is improved and storage and marketing are facilitated. Fixed and rotary screens are the most commonly used in this field.

Food industry

In the food industry, screens play a crucial role in the production of processed foods. From ingredient sorting to contaminant removal, these tools ensure that food products meet quality and safety standards. Vibrating screens are especially valued for their accuracy and efficiency.

Benefits of using screens

The use of screens in industrial processes offers numerous benefits. First, it improves production efficiency by enabling fast and accurate sorting of materials. In addition, contributes to the reduction of operating costs by minimizing waste and optimizing the use of resources. The screens also improve the quality of the final product, which can lead to greater customer satisfaction and improved competitiveness in the marketplace.

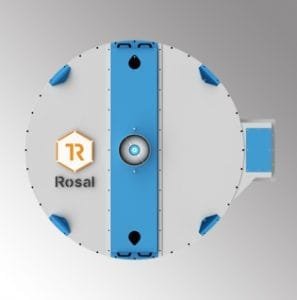

Screens are indispensable tools in a variety of industries. Their ability to separate materials of different sizes efficiently and accurately makes them a key component in many production processes. From mining to agriculture to food, screens improve efficiency, reduce costs and ensure end-product quality. At Rosal Feedmills, we understand the importance of these tools and offer high quality screening solutions to meet each customer's specific needs. Contact with us for more information.