Bucket elevators are essential devices in many industries, especially in those where the following are required requires vertical conveying of bulk materials efficiently and safely. If you are wondering what they are and what types exist, you can't miss our article of Rosal Feed Mills.

What are bucket elevators?

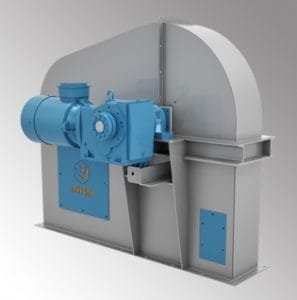

A bucket elevator is composed of a structure consisting of a series of buckets or vessels attached to a belt or chain. These buckets are designed for collect the material at the bottom of the elevator and transport it upwardswhere it is discharged at the desired point. The specific configuration of the buckets and the speed of the belt or chain are adapted according to the type of material and transport requirements of each application. These elevators are commonly used in industrial processing facilities, power plants, agriculture, mining, and in the food industry.among other sectors. They provide an efficient and reliable method for the vertical transport of bulk materials.

Types of bucket elevators

There are several types of bucket elevators to meet different material conveying demands in various industries. The main variation between these types lies in its transport capacitywhich can to be adjusted according to each customer's production needs. From small capacity bucket elevators used in more specific industrial applications, to high capacity models designed to handle large volumes of material, the variety of options available ensures that every customer can find the ideal solution for their requirements.

7 Benefits of bucket elevators

Bucket elevators offer a number of benefits in a variety of industrial applications:

- Transportation efficiencyVertical conveying of bulk materials in an efficient way, minimizing the time and energy required to move large quantities of material.

- Versatilityare suitable for different bulk materials, including grains, minerals, chemicals, foodstuffs, pharmaceuticals, chemicals, foodstuffs, pharmaceuticals and other powdered or granular materials.

- Reduction of contamination and loss of materialClosed buckets can reduce contamination of the environment and prevent loss of material during transport.

- Simple maintenancebucket elevators are generally used for the following applications relatively simple in design and require minimal maintenance, which contributes to lower operating costs.

- Space savingare a space-efficient optionThey allow vertical transport in areas where horizontal space is limited.

- SecurityWhen properly designed and operated, bucket elevators can offer a wide variety of benefits. safe transport of bulk materialsminimizing the risk of occupational accidents and injuries.

- Flow controlBucket elevator systems can be designed with a bucket conveyor device. flow control to regulate the feed rate and unloading, allowing a more controlled and precise process.

Customized elevators for your needs

At feedmillswe stand out for offering customized bucket elevators, designed and manufactured according to the specific needs of each customer. We understand that there is no one-size-fits-all solution for all applications and therefore we work closely with our customers to understand their material conveying requirements and offer a "tailor-made" machine that is perfectly adapted to your production needs. Whether you need a bucket elevator for a small farming operation or for a large-scale industrial installationOur team is ready to provide you with the right solution.

Find out more about our products!

If you are looking for a bucket elevator that perfectly fits the needs of your industry, we invite you to explore our variety of options on our website. Learn more about our custom fabrication services and find out how to our bucket elevators can improve efficiency y productivity in your vertical conveying process.