MABRIK granulators are built with high quality materials and great robustness.

Their design incorporates high dynamic and static load bearings that allow them to work with maximum reliability and in the toughest conditions, such as the granulation of alfalfa, by-products, residues, wood, etc.

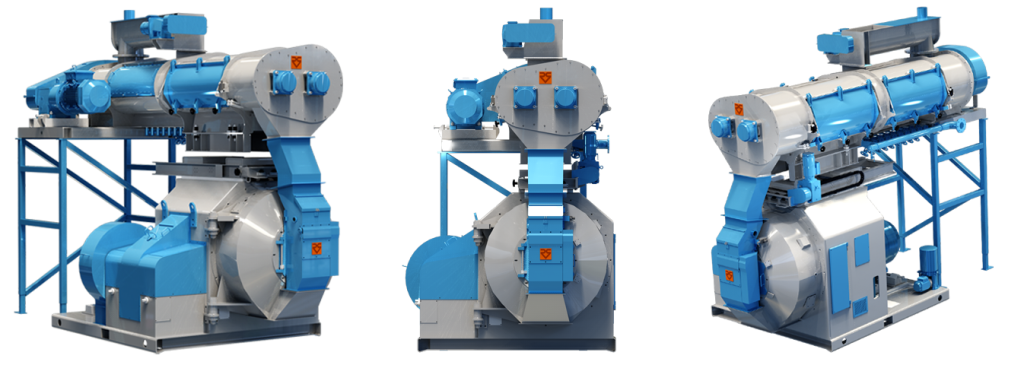

Rosal-Mabrik has created different lines of pelletizing presses for all possible pelletizing fields:

- Pelletizers with a compact design by placing the motor at the top, high performance V-belt transmission, with slip safety control (belt saver) allowing all this a smooth operation with a reduced space and increasing the operational maneuverability.

- Pelletizers from 180 hp which, applying all the advantages of the previous design, a second transmission is added, thus obtaining the most suitable speed for each need. For pelletizers from 340 hp, the secondary or central group transmission is by means of a single high-performance toothed belt capable of transmitting up to 1200 hp.

- Granulators with double transmission allow reaching the minimum speeds necessary for the most difficult products, placing the main engine at the rear, with no space limitations in this type of installation.

Features - Mabrik Pelleting Press

- The product inlet and the pelletizing chamber, together with the door, are made of stainless steel.

- The pelletizer door incorporates a safety detector with delay, not allowing its opening until the die and rollers are completely stopped.

- All models incorporate a relief gate and can be supplied with different die widths with two or three rollers, depending on the product to be pelletized.

- Different feeder-conditioners can be incorporated in each model, depending on the needs or products to be processed.