GRINDING

Hammer mill

Grinding is one of the most important processes in feed production. The objective is to find the optimum particle size by milling the raw material (wheat, corn, barley, etc.).

The new Rosal hammer mill model has revolutionized the industry due to the productivity guarantees it offers, as well as its innovative side opening system that makes grid changes easier.

Features

Performance

High-efficiency industrial hammer mills

Our hammer mills are designed to provide efficient and high quality grinding. They are equipped with a rotor equipped with hammers that rotate at high speeds, impacting the product to be ground. This provides efficient grinding depending on the final product to be produced: livestock feed, pet food or fish feed.

The hammer mill consists of a steel monobloc body of reinforced construction supported on a base with special anti-vibration dampers for floor mounting.

Design

Simplified maintenance for optimum performance

The Rosal hammer mills are equipped with two-section circular screens, easily interchangeable from the outside.

The rotor, with reversible clockwise or counterclockwise rotation, ensures maximum utilization of the hammers and sieves.

In addition, easy-access side doors allow simple and quick control for changing hammers, optimizing operational efficiency.

Models

Thinking of all possible grinding fields, Rosal has created different constructive lines. For each hammer mill series, there is the option of installing larger motorizations.

MMR models

- Hammer mills designed for the livestock industry.

- The motor operates at a speed of 1500 revolutions per minute (rpm).

| Model | Motor power (HP) | Mill weight (KG) | Feeder weight (KG) |

|---|---|---|---|

| MMR-05X10 | 75 / 100 / 125 / 150 | 3003 / 3193 / 3233 / 3468 | 220 |

| MMR-10X20 | 150 / 180 / 220 / 270 / 340 | 6106 / 6166 / 6206 / 6366 / 6816 | 320 |

| MMR-15X30 | 340 / 430 / 480 / 540 | 7080 / 7255 / 7295 / 7615 | 485 |

VRE models

- Hammer mills designed for petfood and aquaculture.

- The motor operates at a speed of 3000 revolutions per minute (rpm).

| Model | Motor power (HP) | Mill weight (KG) | Weight with feeder (KG) |

|---|---|---|---|

| VRE-75 | 75 / 100 | 1450 / 1650 | 1800 / 2000 |

| VRE-150 | 125 / 150 | 1950 / 2100 | 2200 /2450 |

| VRE-220 | 180 / 220 | 2850 / 2950 | 3200 / 3300 |

| VRE-220 | 220 / 270 | 3400 / 3700 | 4100 / 4400 |

| VRE-440 | 340 / 440 | 5100 / 5300 | 5800 / 5610 |

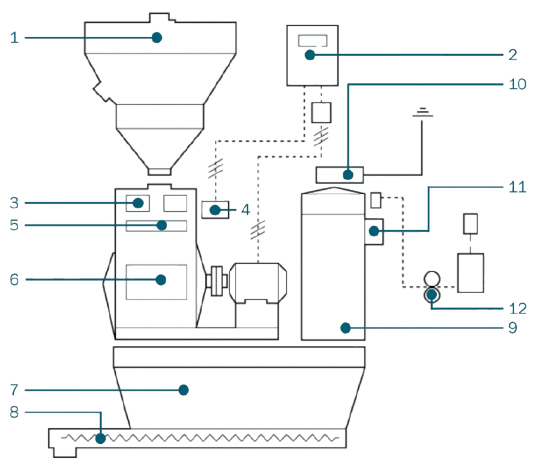

Main components

1. Separating screen.

2. Automatic feed regulator.

3. Roller feeder.

4. Motor reducer power supply.

9. Sleeve filter.

10. Centrifugal vacuum cleaner.

11. Air regulation electric panel.

12. Filter compressor.

5. Super strong magnet.

6. Grinding mill.

7. Decompression chamber.

8. Extractor thread.

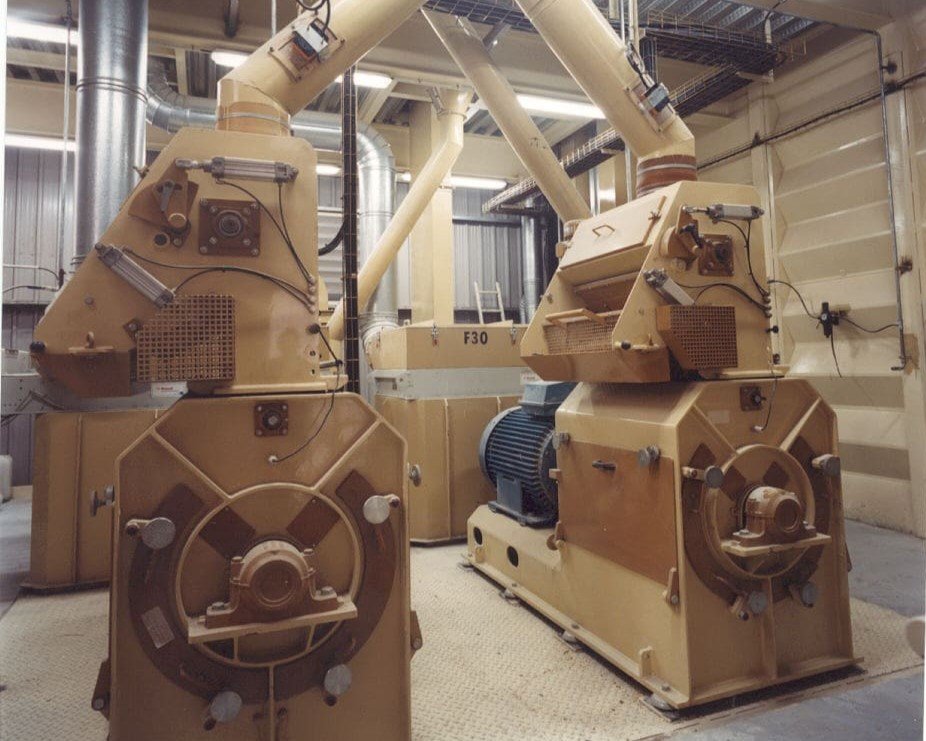

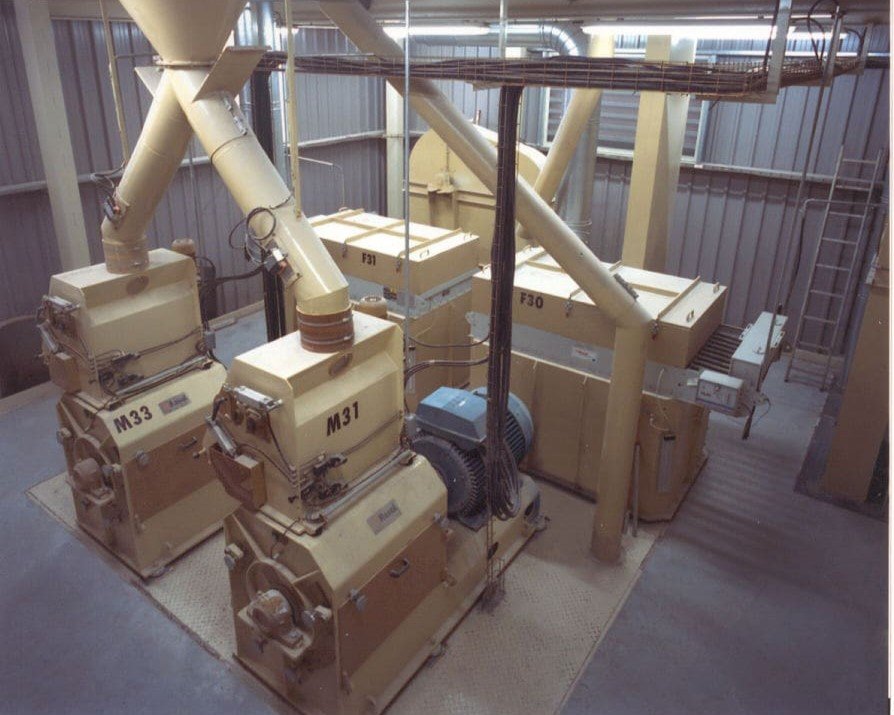

Image gallery

Related machinery

Roller mill

The roller mill is ideal for installations that require homogeneous grinding with a minimum percentage of fines.

Flaking mill

The flaking mill produces cereal flakes, ideal for livestock due to their excellent digestibility.